01

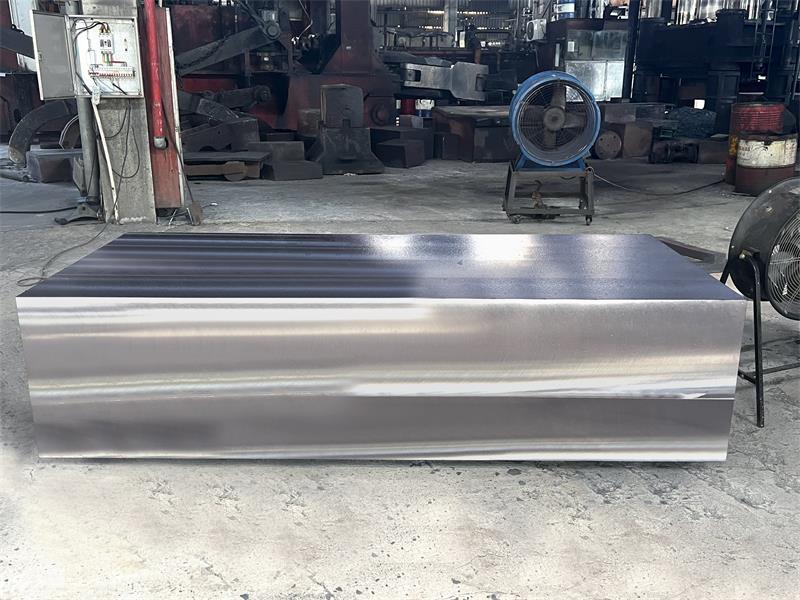

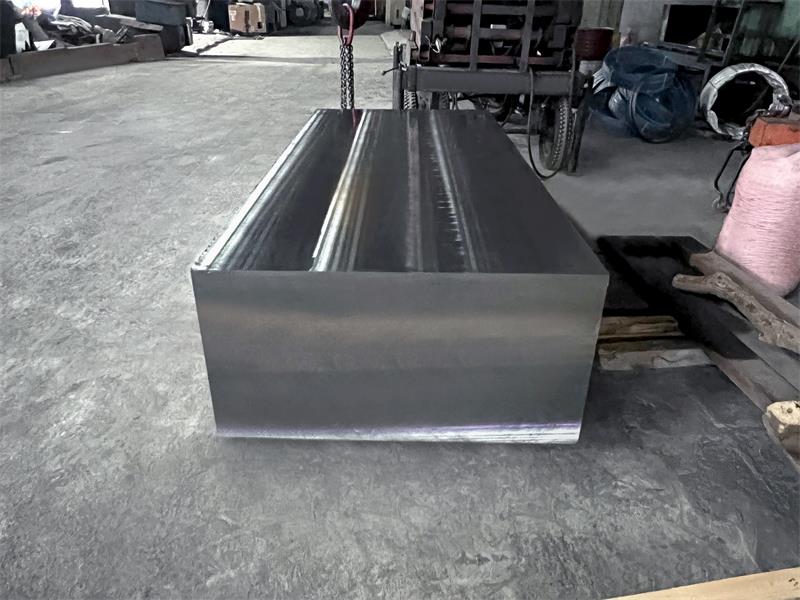

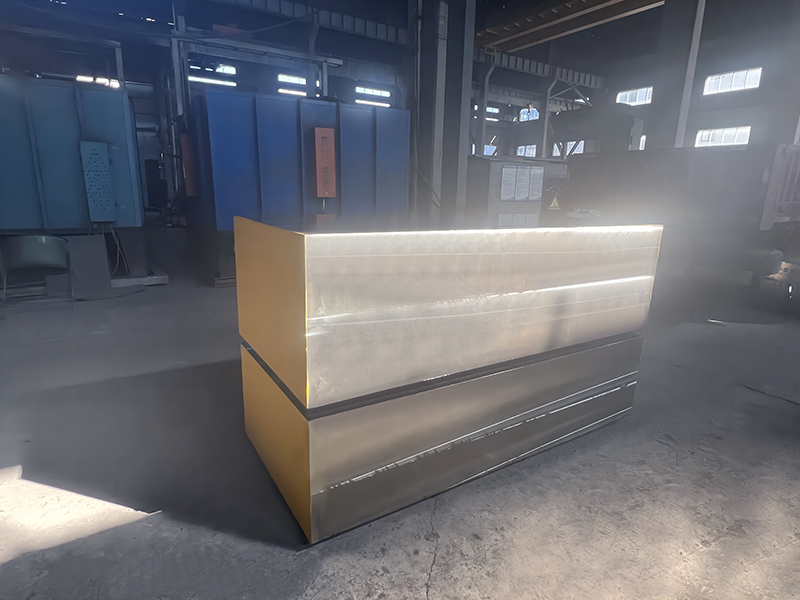

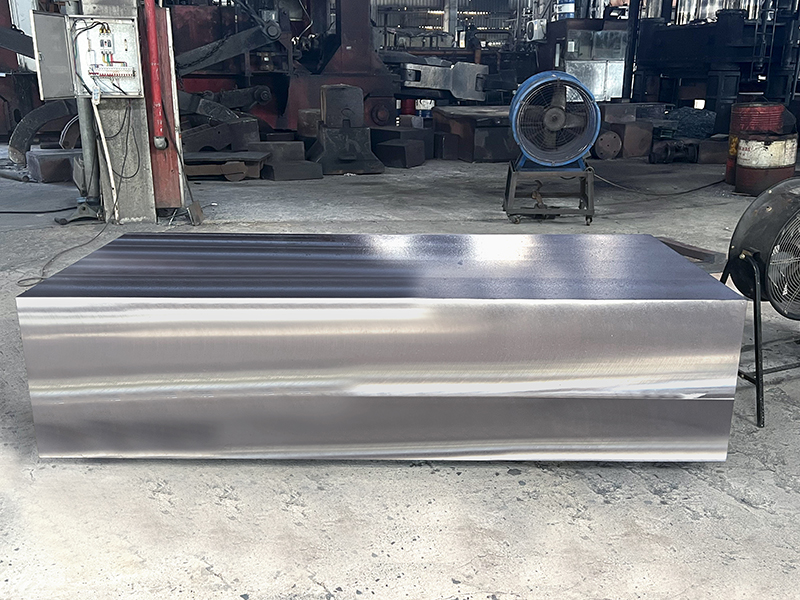

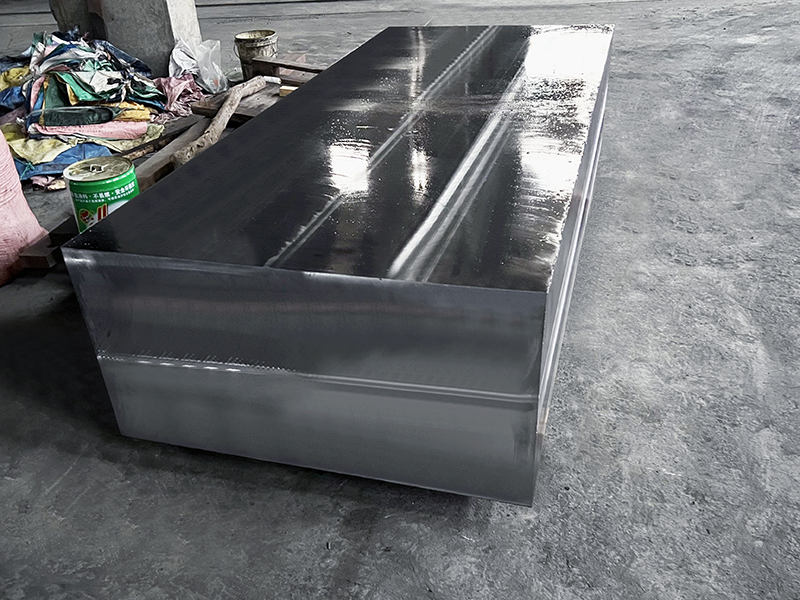

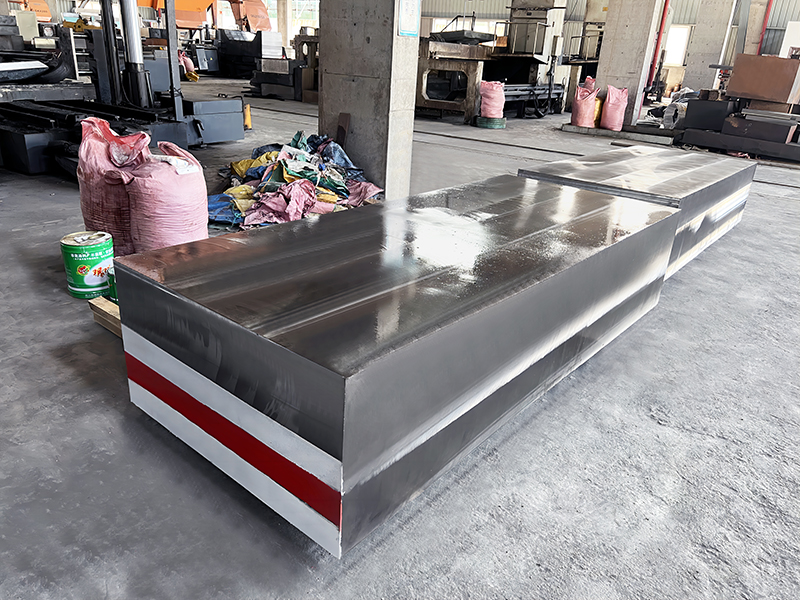

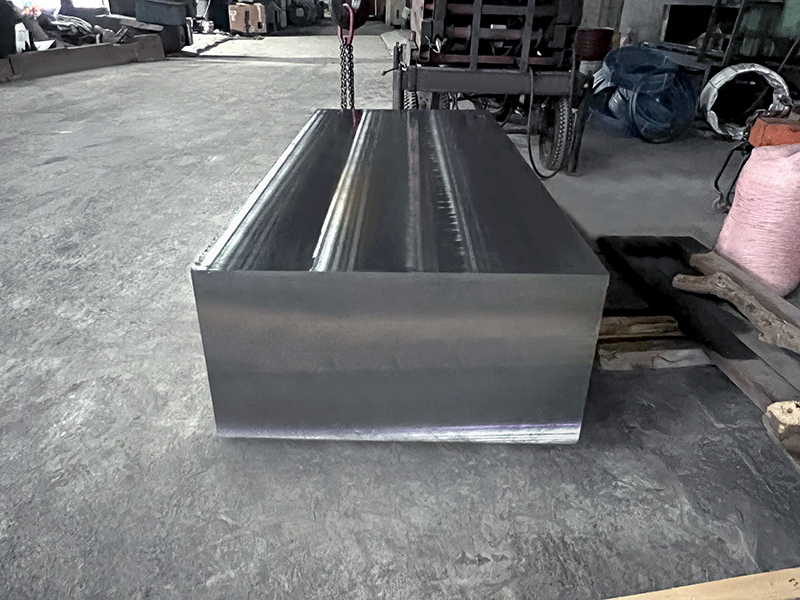

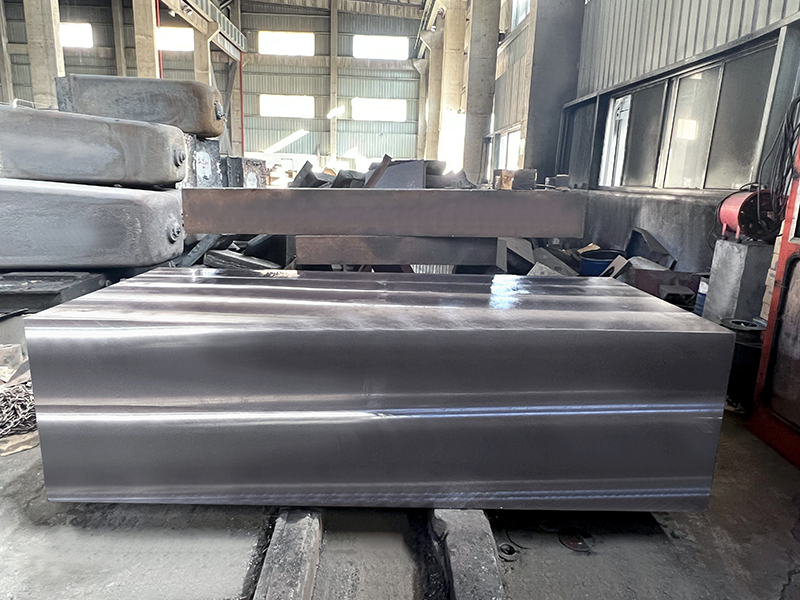

H13/1.2344/ 4Cr5MoSiV1 Steel

H13 mold steel characteristics

1.It has high hardenability and high toughness.

2.Excellent resistance to thermal cracking, and can be water-cooled in the workplace.

3.It has medium wear resistance. Carburizing or nitriding processes can also be used to improve its surface hardness, but the thermal crack resistance will be slightly reduced.

4.Because of its low carbon content, the secondary hardening ability during tempering is poor.

5.It has the ability to resist softening at higher temperatures, but the hardness drops rapidly when the operating temperature is higher than 540℃ (1000℉) (that is, the working temperature it can withstand is 540℃ ).

6.The deformation caused by heat treatment is small.

7.Medium and high machinability.

8.Moderate resistance to decarburization.

Simply put, H13 mold steel has good hardenability, good high-temperature comprehensive mechanical properties, good heat resistance and thermal fatigue resistance, and good resistance to liquid metal erosion.

description2

Applicable scope of H13 mold steel

1.Used to manufacture forging dies with large impact loads , complex shapes and high precision;

2.Used in die forging hammer dies, aluminum alloy die-casting dies, hot extrusion dies, high-speed precision forging dies and forging press dies, etc.;

3.Used to manufacture plastic films that require long service life.

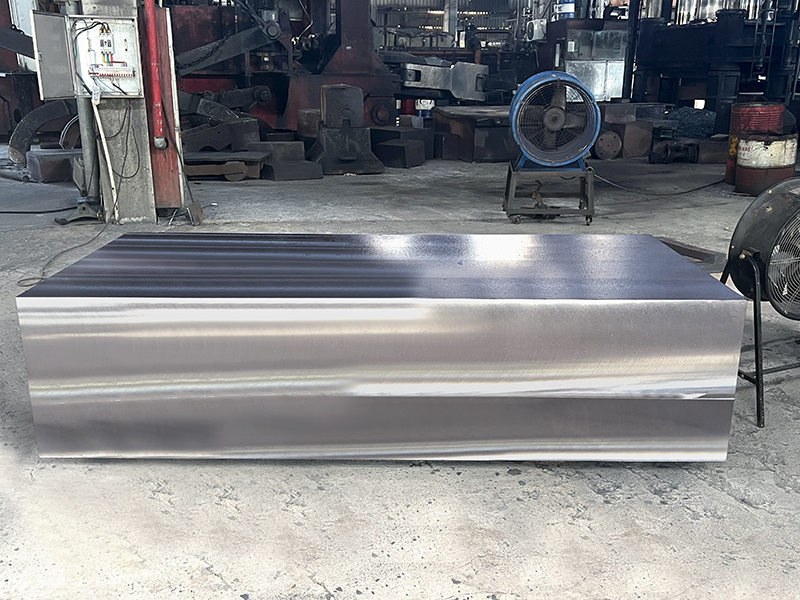

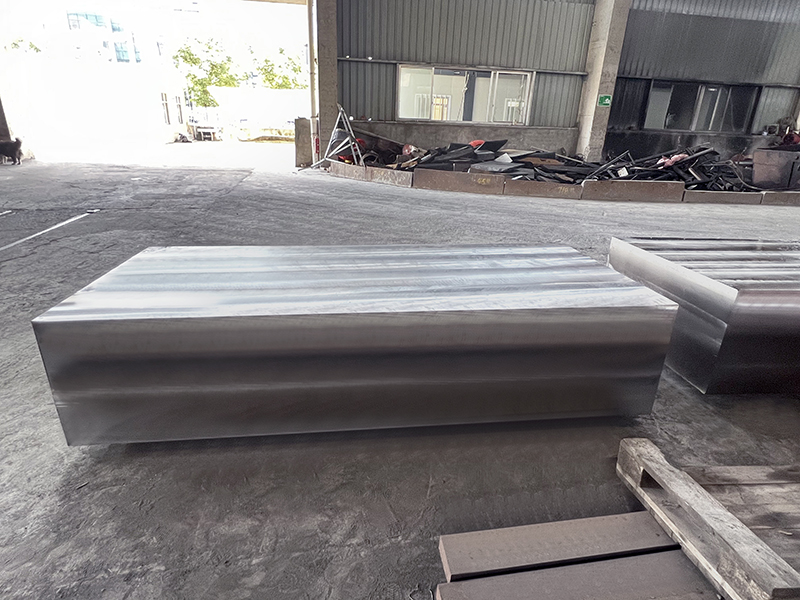

Sanyao Company can provide customers with customized forging (including size, hardness, eye bolt, rough machining, quenching and tempering, rough surface grinding,fine surface grinding,etc.) to meet customers' individual needs.

Phone

Phone Send Email

Send Email