0102030405

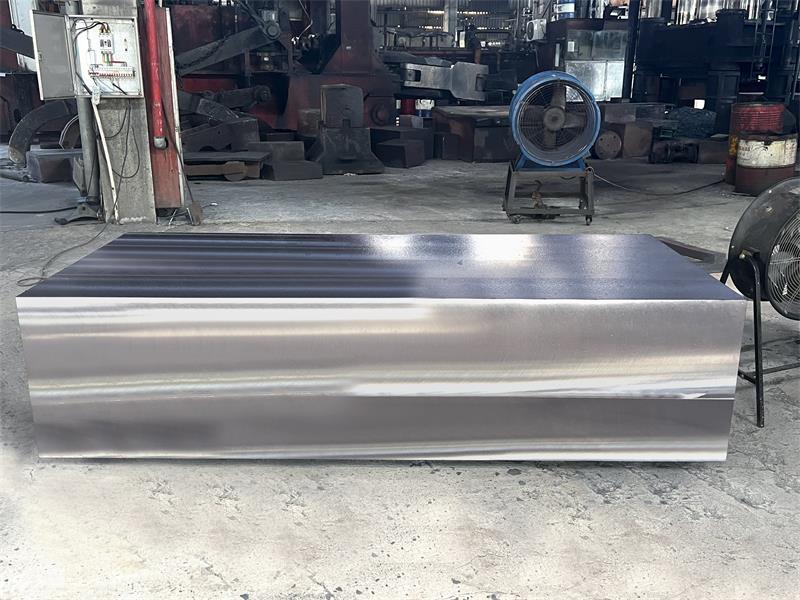

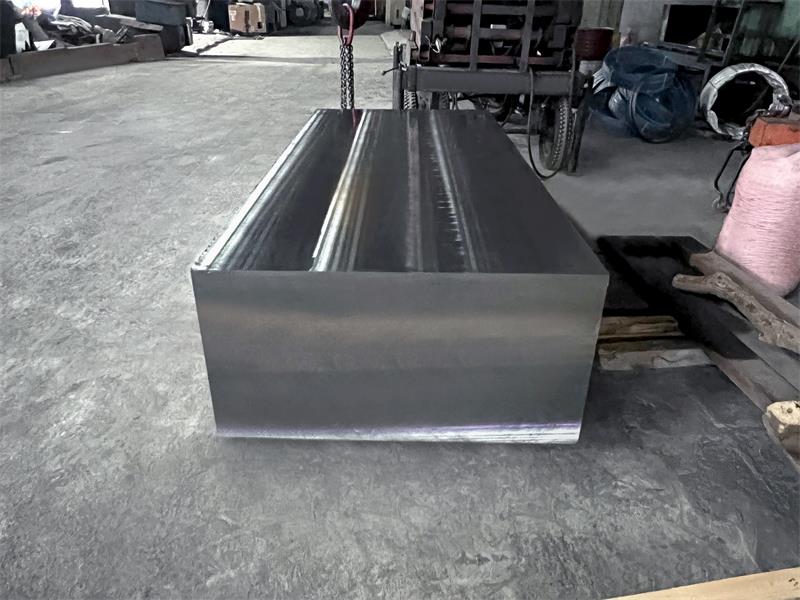

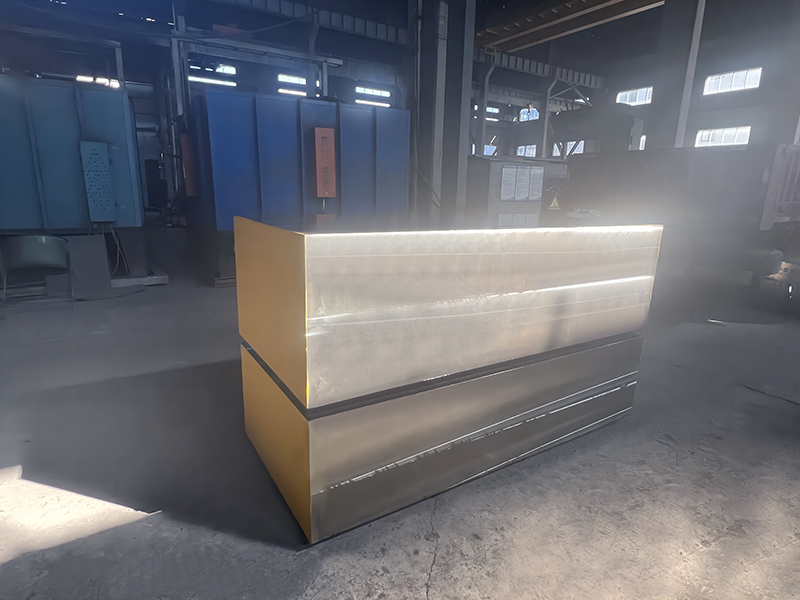

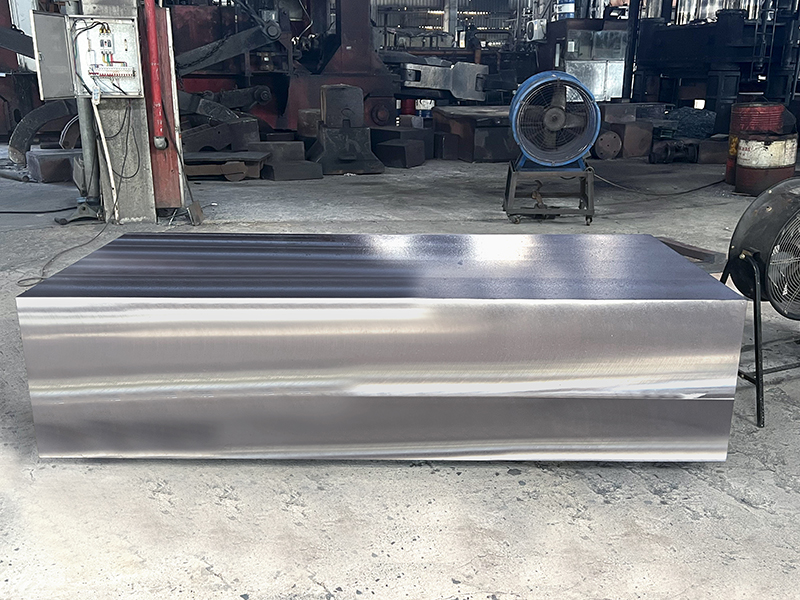

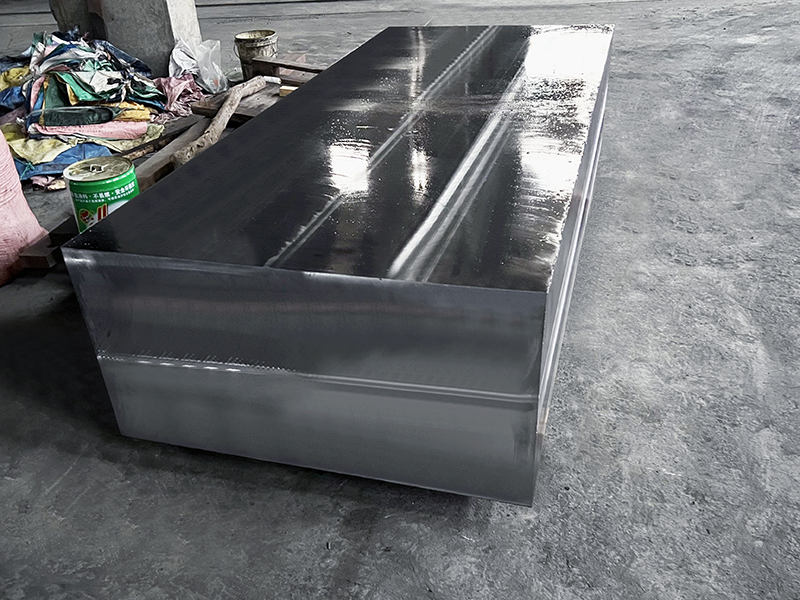

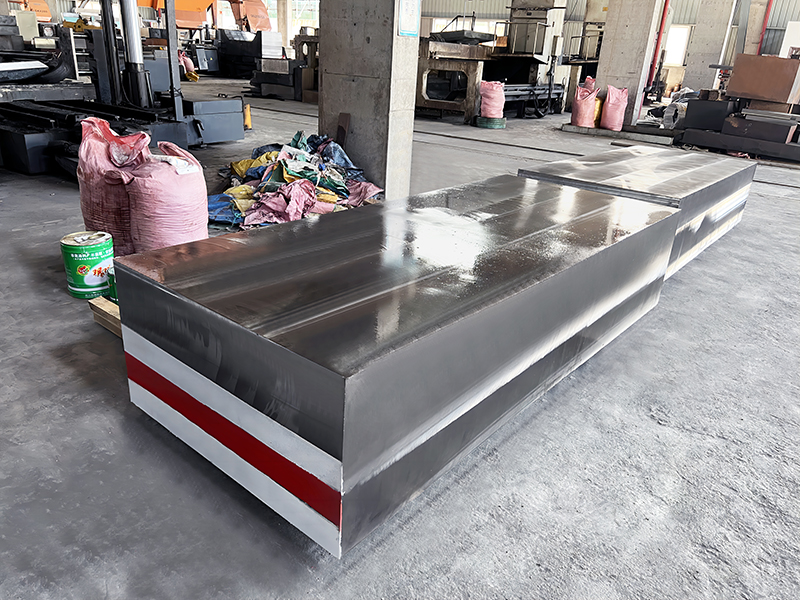

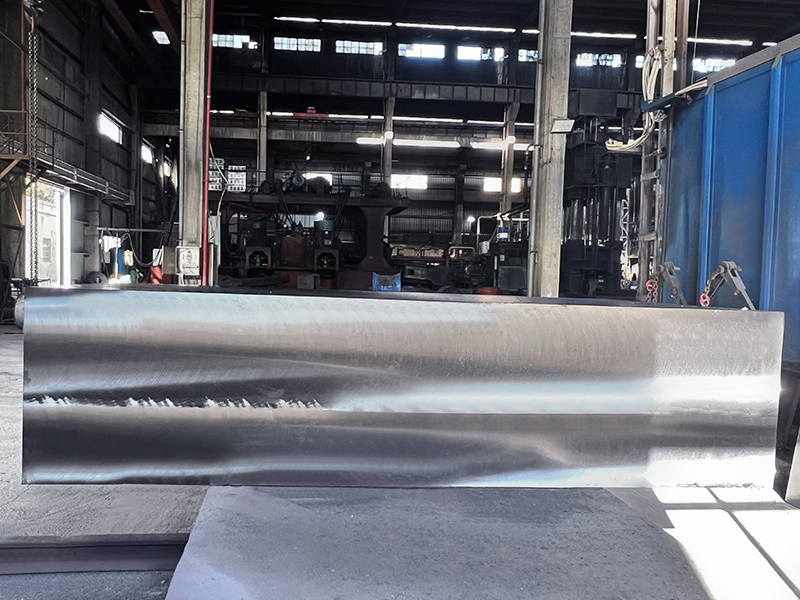

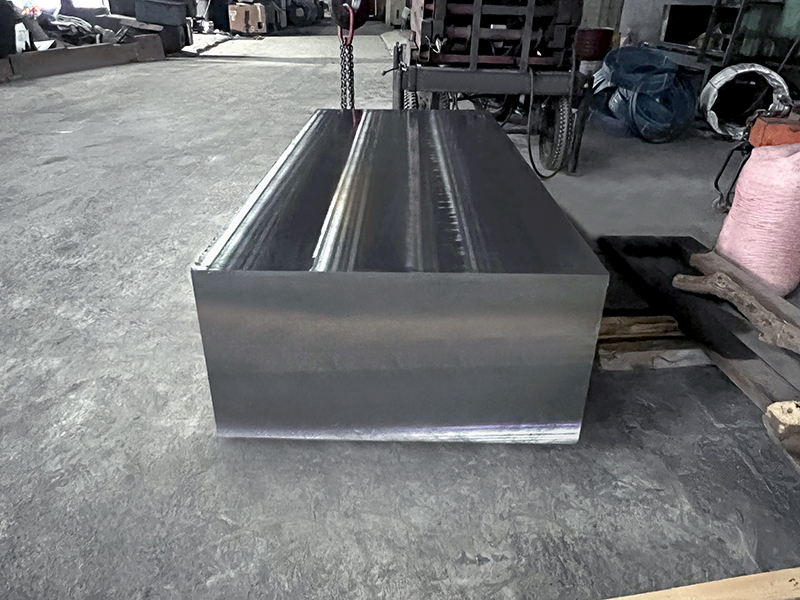

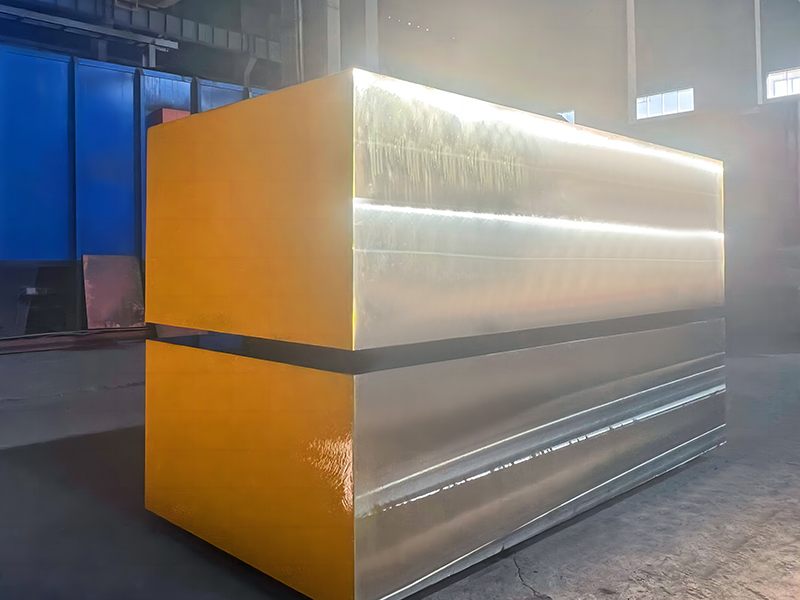

30Cr13 (3Cr13) Stainless Steel

30Cr13 (3Cr13) stainless steel characteristics

1.This steel has good machining performance. After heat treatment (quenching and tempering), it has excellent corrosion resistance , polishing performance , high strength and wear resistance .

2. After quenching and tempering, the 30Cr13 material with a hardness below HRC30 has better processability and can easily achieve better surface quality. Although the surface quality of parts machined when the hardness is greater than HRC30 is good, the tools are prone to wear. Therefore, after the material enters the factory, it is first quenched and tempered to a hardness of HRC25~30 , and then cut.

3. This steel has higher hardness and has higher strength, hardness and hardenability than 12 Cr13(1Cr13/410 ) and 20Cr13(2Cr13) steel after quenching . But the weldability is not as good as 12Cr13 and 20Cr13. Its price is the lowest among stainless steel balls, and it is suitable for working environments with common requirements for stainless steel.

description2

30Cr13 (3Cr13) stainless steel application scope

1.Suitable for manufacturing plastic molds that bear high load, high wear resistance and are exposed to corrosive media;

2.Applicable to all types of precision machinery, bearings, electrical leaks, equipment, instruments, meters, transportation vehicles, household appliances, etc.;

3.Mostly used to manufacture parts that are resistant to atmospheric, steam, water and oxidizing acid corrosion;

4.Mainly used for high-strength components and wear parts that bear high stress loads and work in certain corrosive media. For example, cutting tools and springs that work below 300℃, and shafts, bolts, valves, bearings, etc. that work below 400℃ are also used as measuring instruments and medical tools.

Sanyao Company can provide customers with customized forging (including size, hardness, eye bolt, rough machining, quenching and tempering, rough surface grinding,fine surface grinding,etc.) to meet customers' individual needs.

Phone

Phone Send Email

Send Email