0102030405

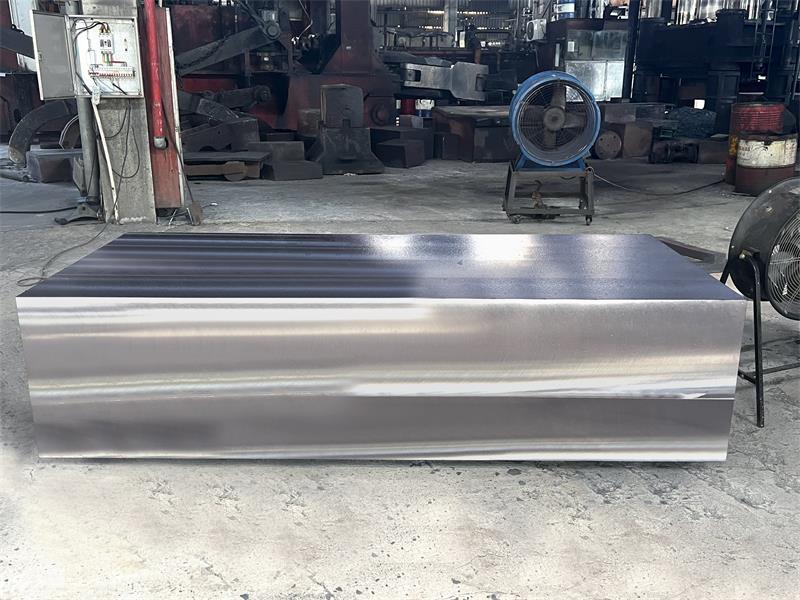

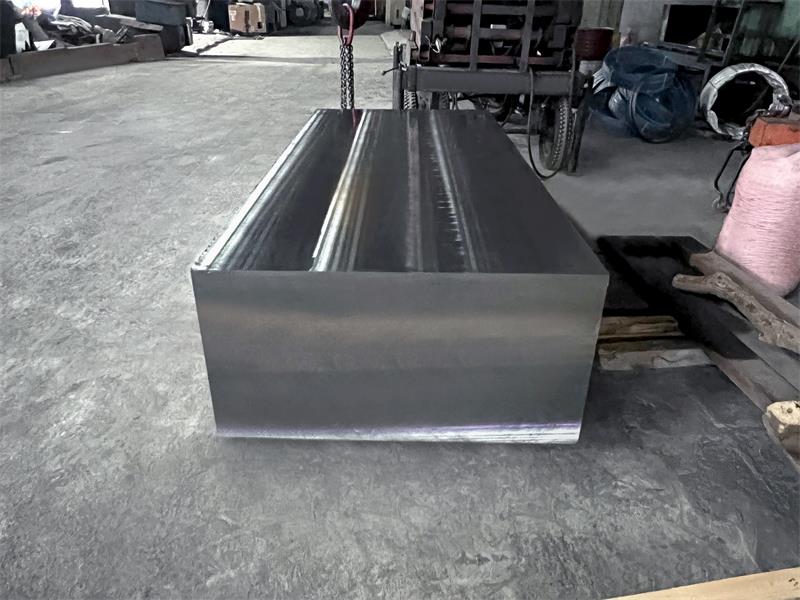

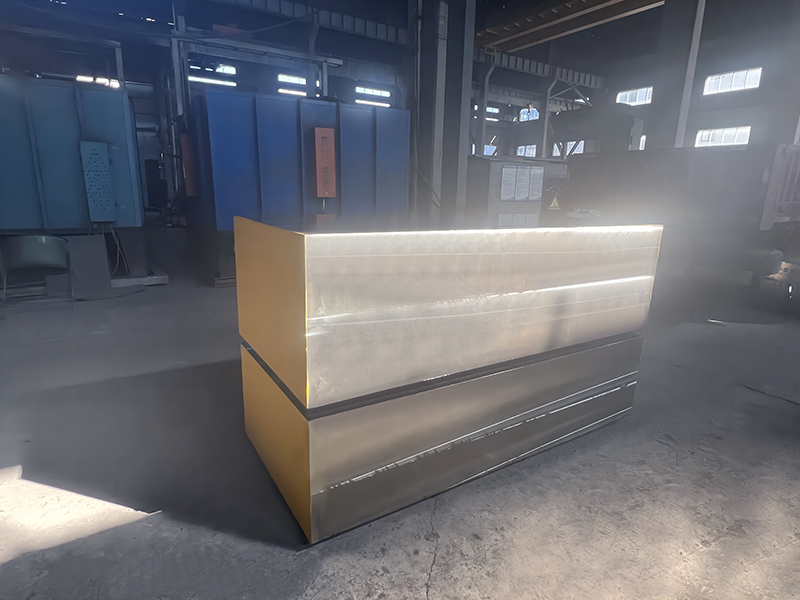

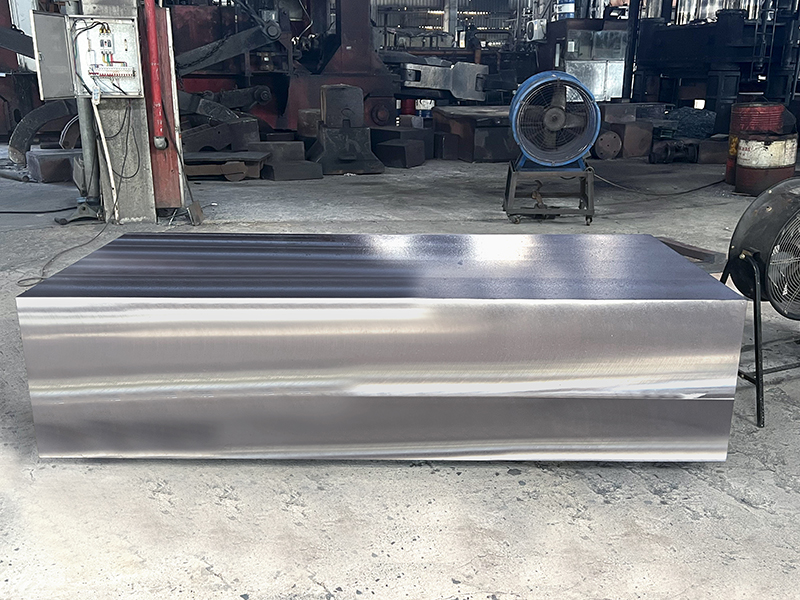

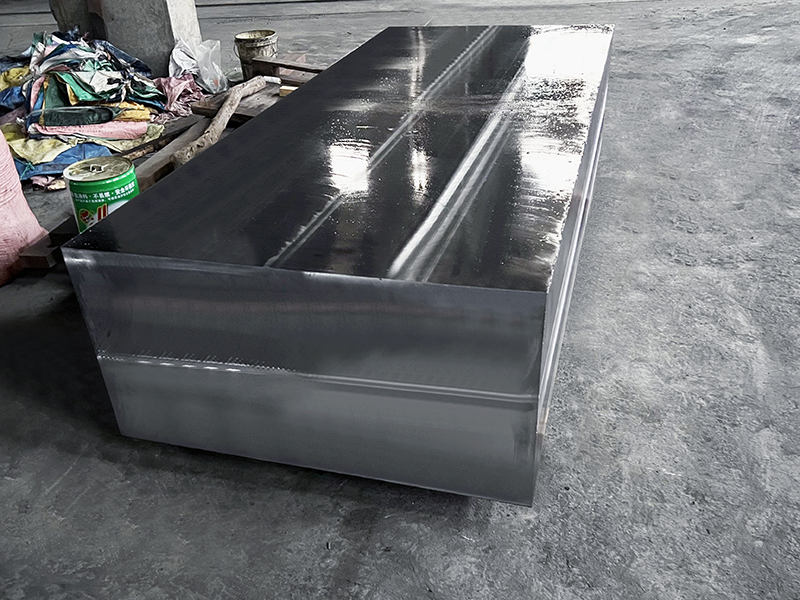

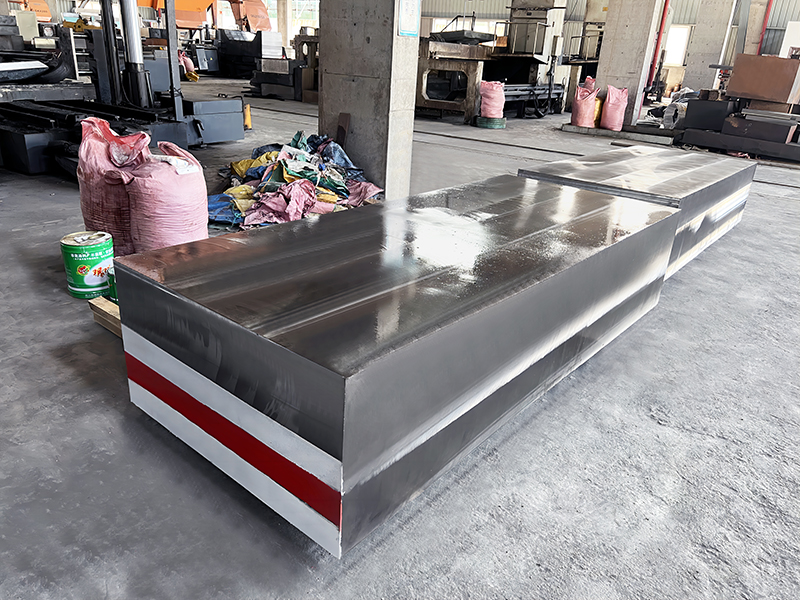

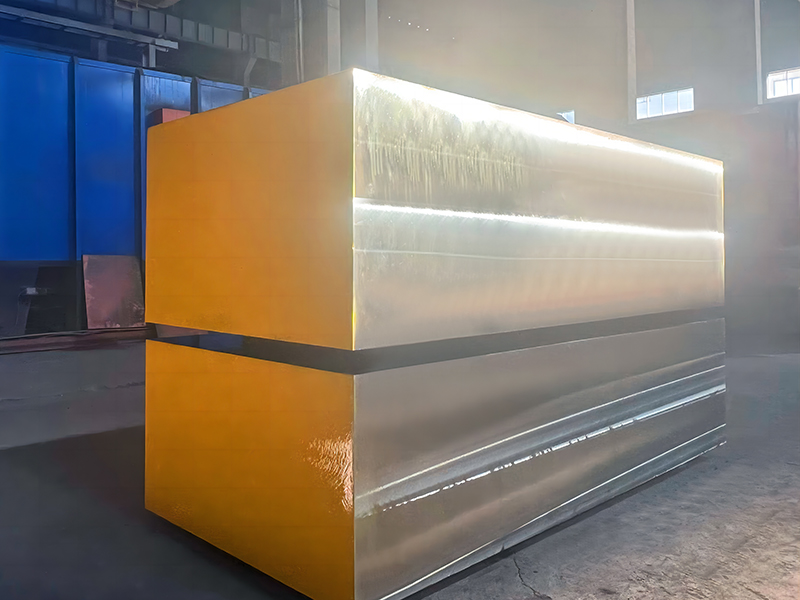

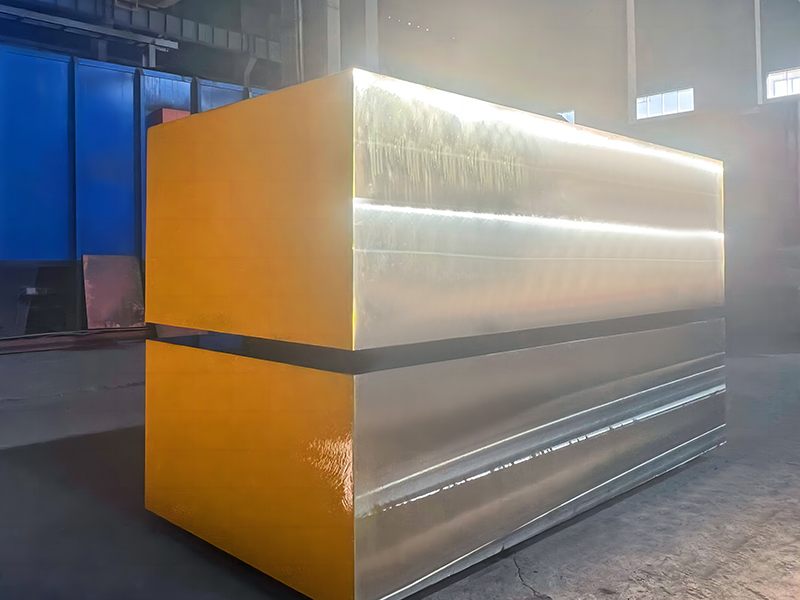

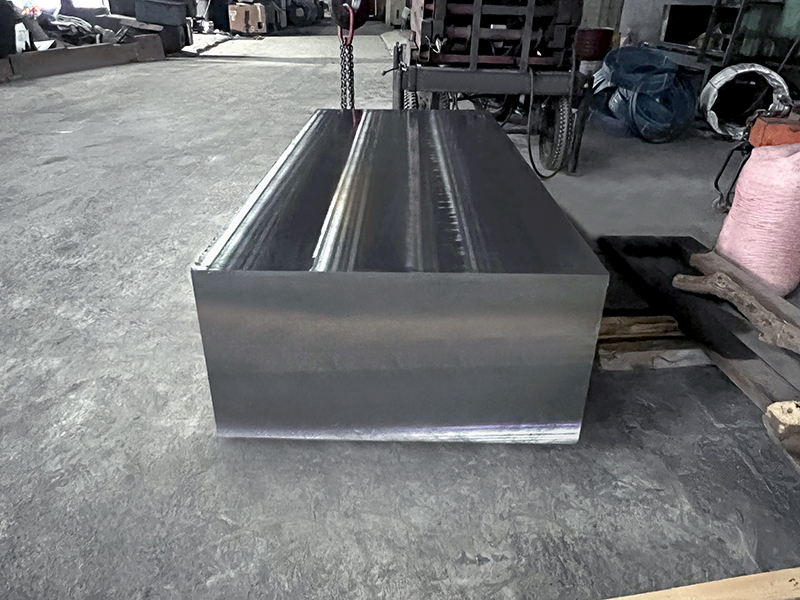

38CrMoAl/41CrAlMo74 Alloy Structural Steel

38CrMoAl alloy structural steel characteristics

1.38CrMoAl steel has high strength and surface hardness, and good fatigue resistance.

2.It has excellent mechanical properties and processing performance, and can perform various mechanical processing and welding operations to manufacture various complex parts and structures.

3.It has excellent wear resistance and good heat resistance, suitable for use in high wear and high temperature environments, reducing material fatigue and damage caused by wear.

4.It has corrosion resistance, but its hardenability is not high.

38CrMoAl VS 42CrMo:

38CrMoAl and 42CrMo are both high-quality alloy steel materials with their own advantages and scope of application.

If you need materials with wear resistance and high strength, you can choose 38CrMoAl;

If you need high hardness, toughness and corrosion resistance, you can choose 42CrMo.

Therefore, it is very important to choose appropriate materials according to specific application scenarios and needs.

description2

38CrMoAl alloy structural steel application scope

1.Used to make nitrided parts with high wear resistance, high fatigue strength and considerable strength, and high dimensional accuracy after processing, such as imitations, cylinder liners, gears, high-pressure valves, boring bars, worms, grinder spindles, etc. However, larger parts should not be used.

2.Mainly used for nitrided parts with precise dimensions after heat treatment, or various nitrided parts with low impact load and high wear resistance, such as boring bars, grinder spindles, automatic lathe spindles, worms, precision screws, precision Gears, high-pressure valves, valve stems, gauges, templates, rollers, imitations, cylinder blocks, compressor piston rods, governors, rotating sleeves, fixed sleeves on steam turbines, various wear-resistant parts on rubber and plastic extruders pieces etc.

3. Widely used in aviation, aerospace, automobile, machinery manufacturing and other fields.

Sanyao Company can provide customers with customized forging (including size, hardness, eye bolt, rough machining, quenching and tempering, rough surface grinding,fine surface grinding,etc.) to meet customers' individual needs.

Phone

Phone Send Email

Send Email