01

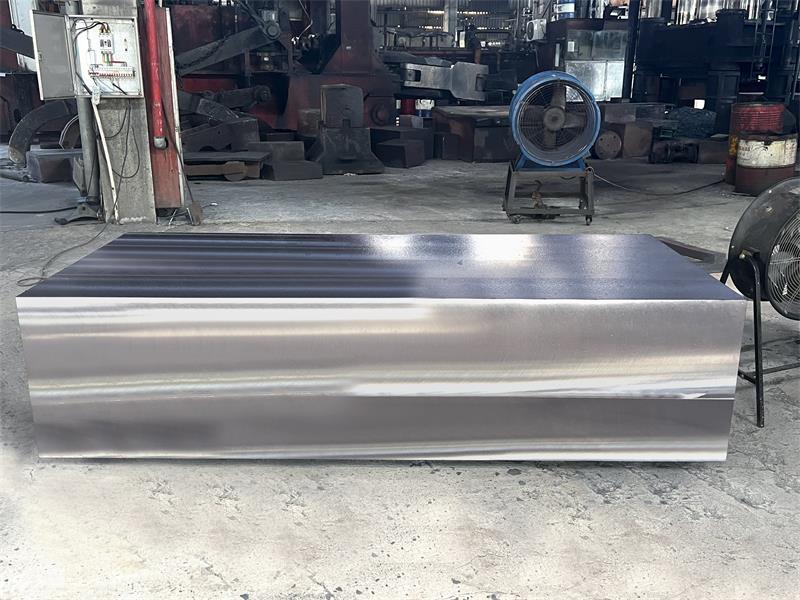

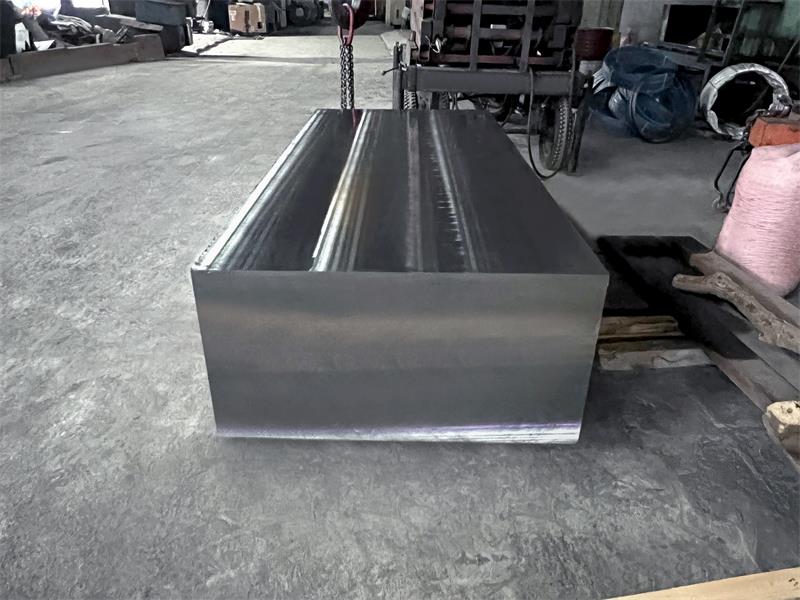

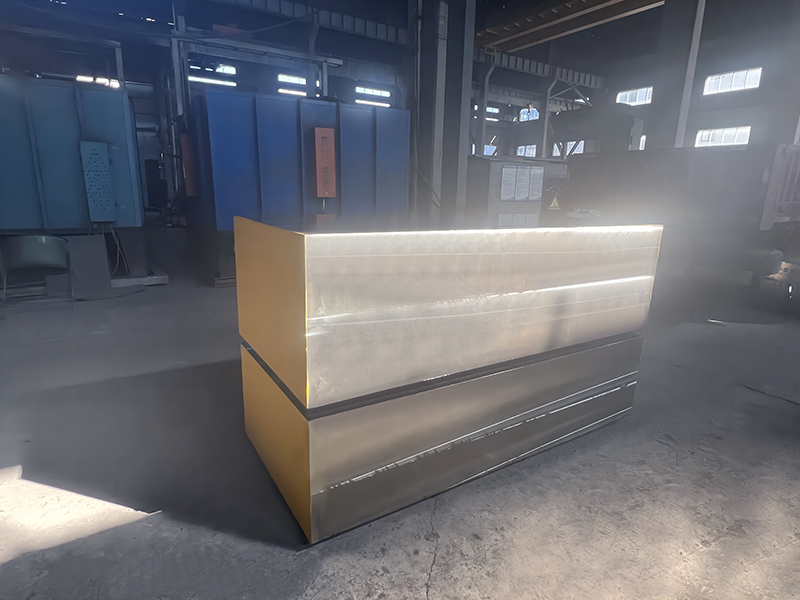

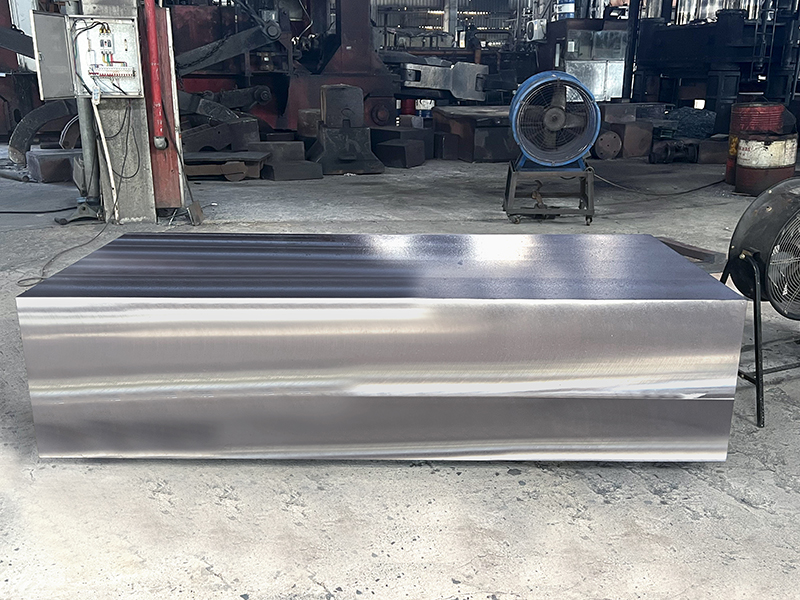

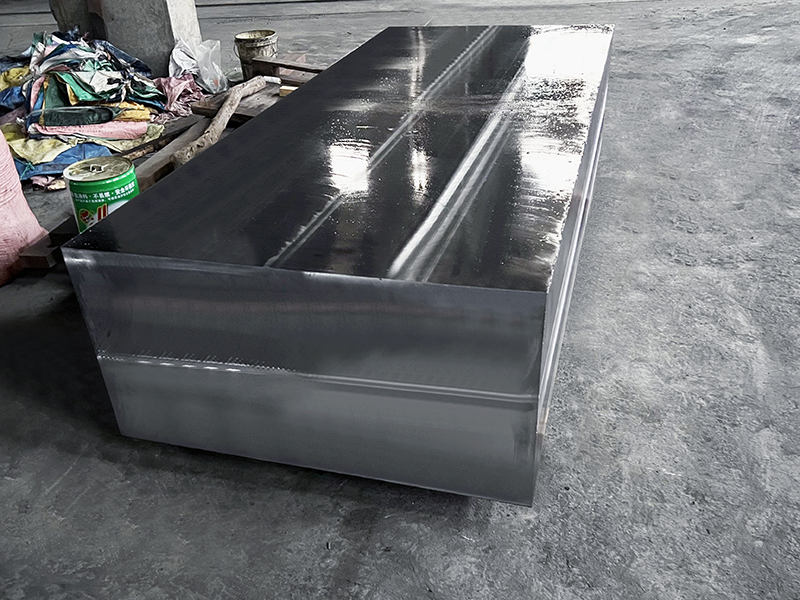

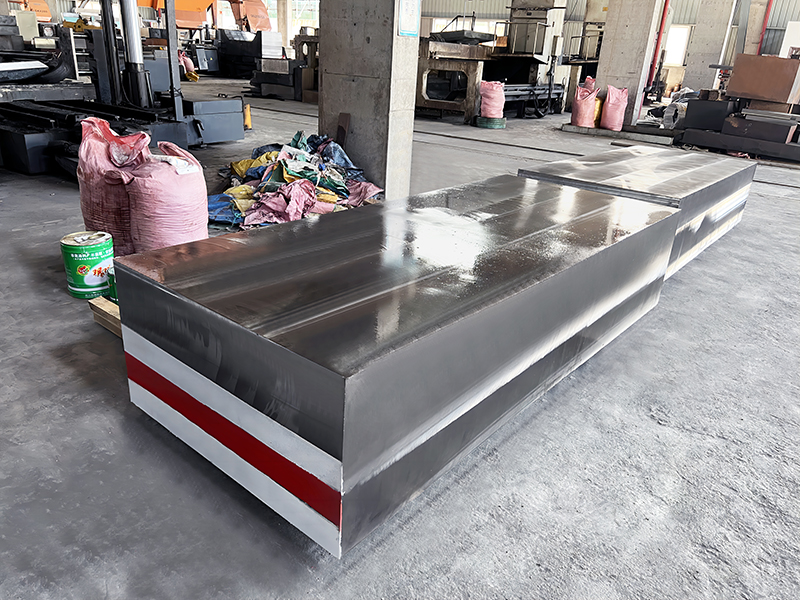

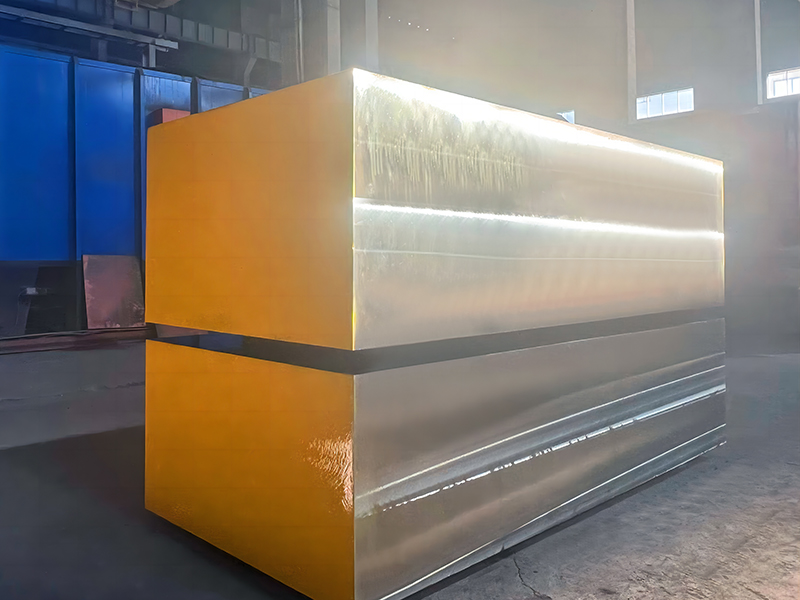

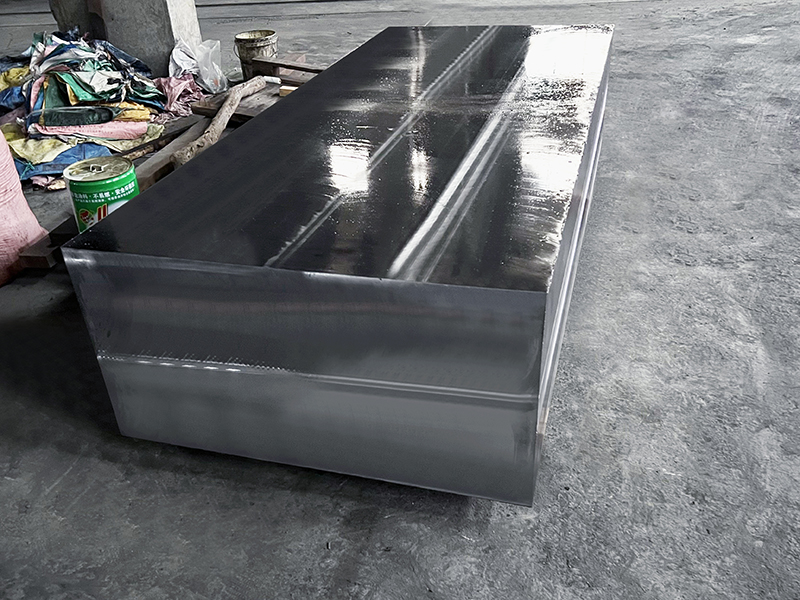

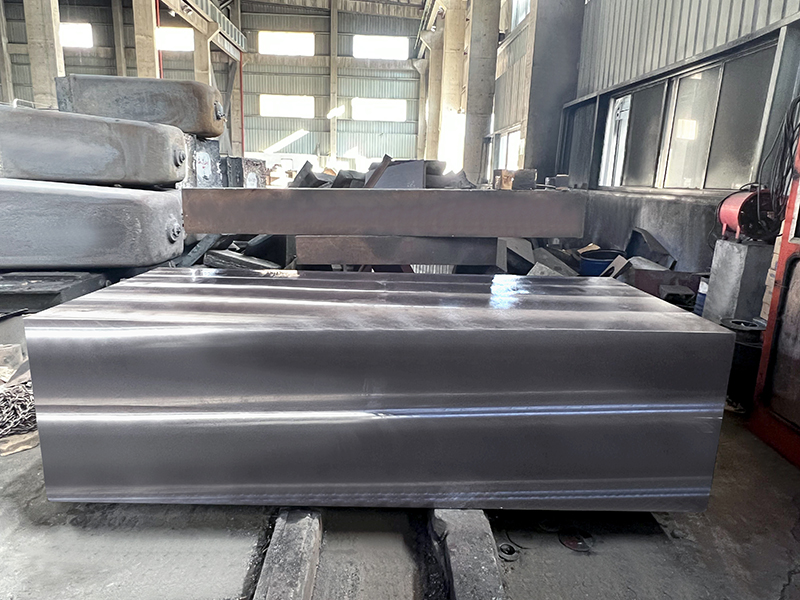

S45C Carbon Structural Steel

S45C carbon structural steel characteristics

1.Able to withstand high-intensity and heavy-load working conditions.

2.It has excellent mechanical properties and wear resistance. It can maintain good performance and stability no matter in high or low temperature environments. But this is a medium carbon steel and its quenching performance is not good.

3.High-quality carbon structural steel with low hardness and easy cutting and processing. It has good plasticity and processability and can be easily processed by cutting, cold forging, heat treatment and other processing operations. But the welding performance is average. It is often used as templates, pins, guide posts, etc. in molds, but it must be heat treated.

4.The surface hardness after quenching and tempering is between HRC20 and HRC30. Due to poor permeability, the core hardness changes with the thickness of the part. The thicker the thickness, the lower the hardness.

5.The quenching hardness of steel is between HRC55~58, and the limit value can reach HRC62; but it is not recommended. When the steel hardness is above HRC50, cracks are more likely to occur.

6.The parts after quenching and tempering treatment have good comprehensive mechanical properties and are widely used in motorcycles and automobiles, especially those connecting rods, bolts, gears and shafts that work under alternating loads and must withstand huge friction during work. The method of quenching is usually used to improve its hardness, wear resistance and service life

description2

Scope of application of S45C carbon structural steel

1.It is ideal for professional machinery and equipment and automobile manufacturing;

2.Used to manufacture machine parts subject to high loads, such as crankshafts, spindles, spindles, gear shafts, chains, etc.;

3.Used to manufacture high-strength moving parts, such as shafts, gears, bolts, worms, etc.

Sanyao Company can provide customers with customized forging (including size, hardness, eye bolt, rough machining, quenching and tempering, rough surface grinding,fine surface grinding,etc.) to meet customers' individual needs.

Phone

Phone Send Email

Send Email