01

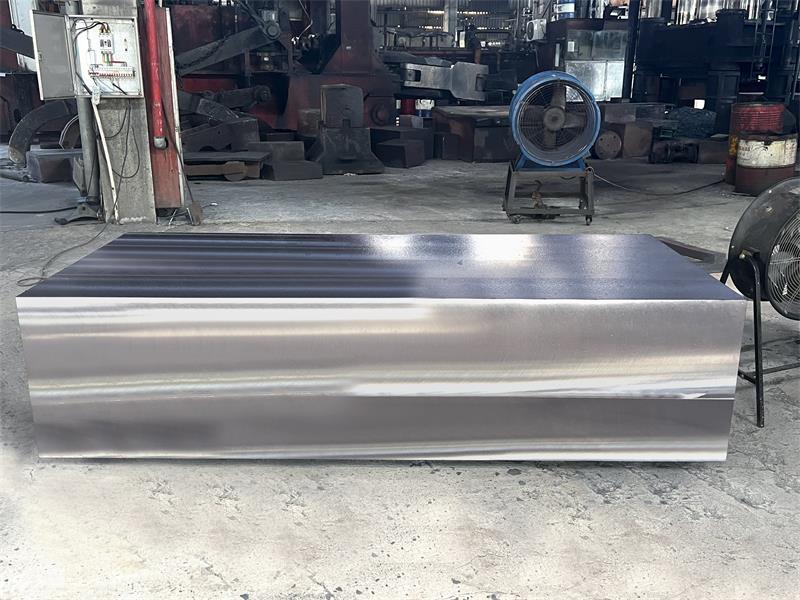

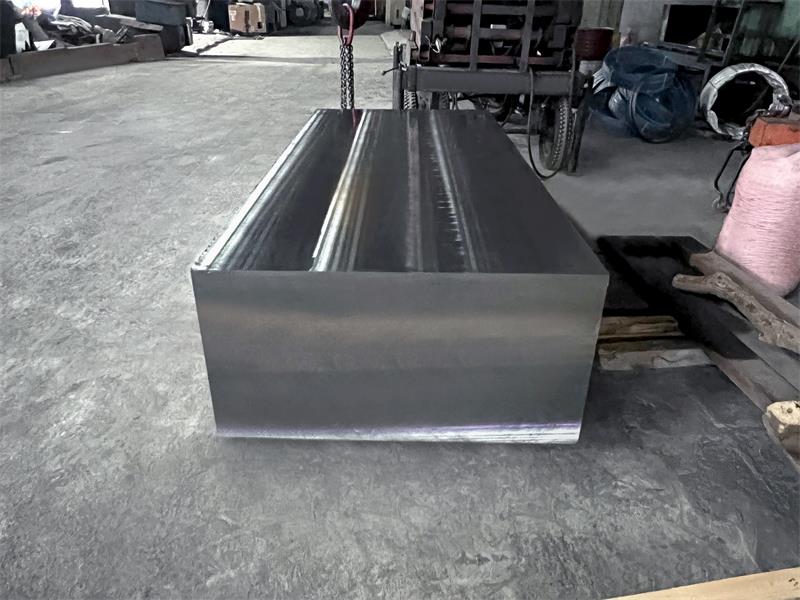

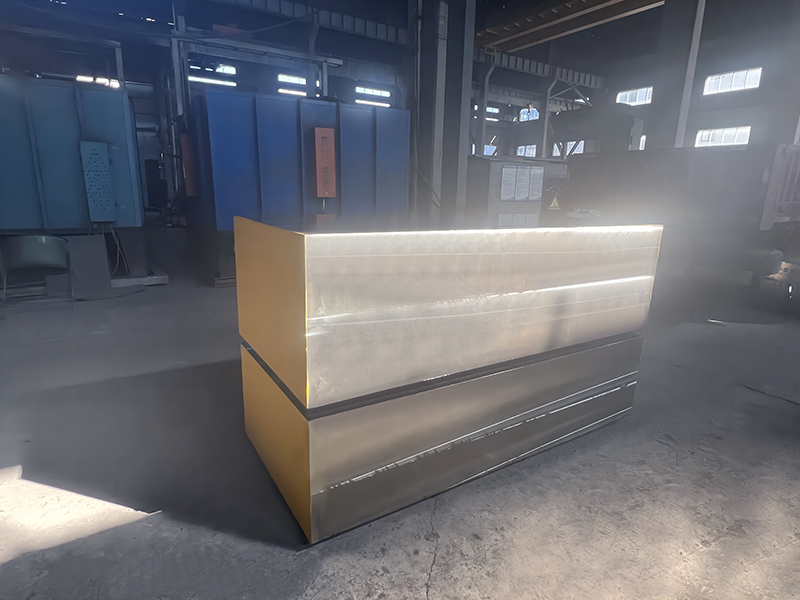

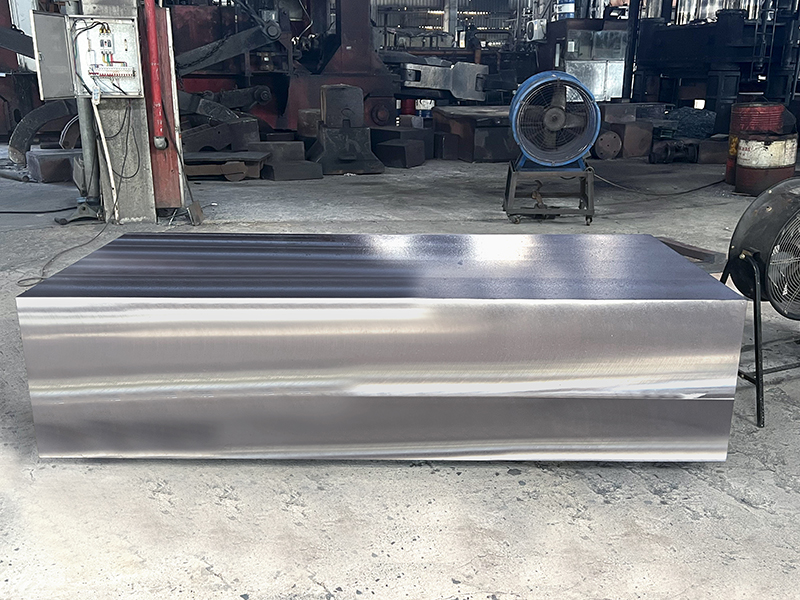

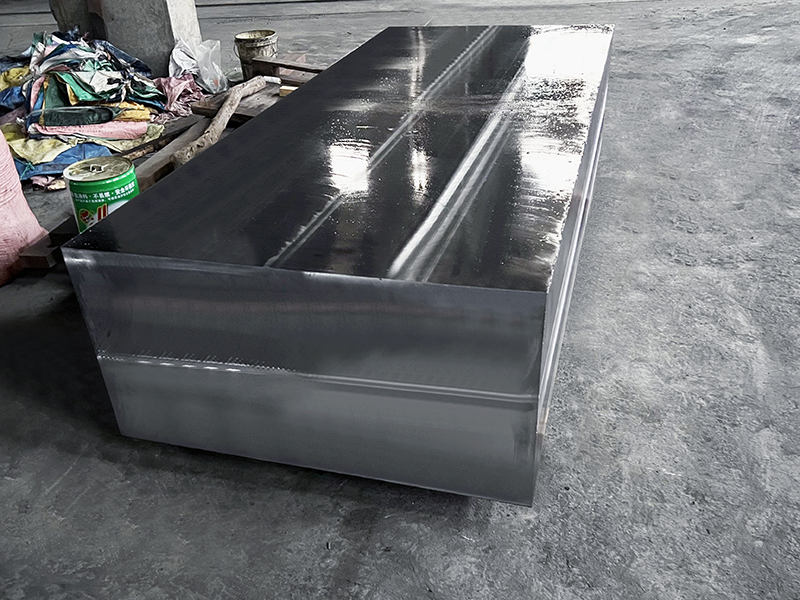

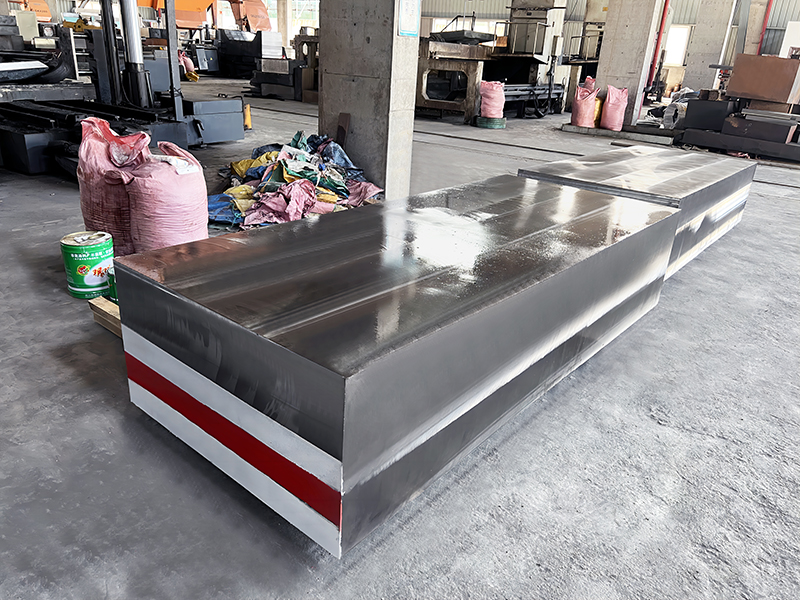

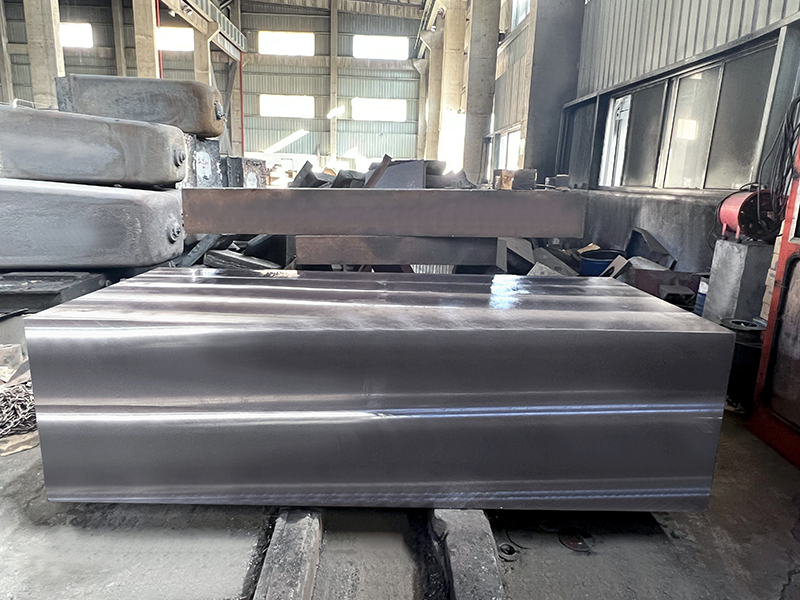

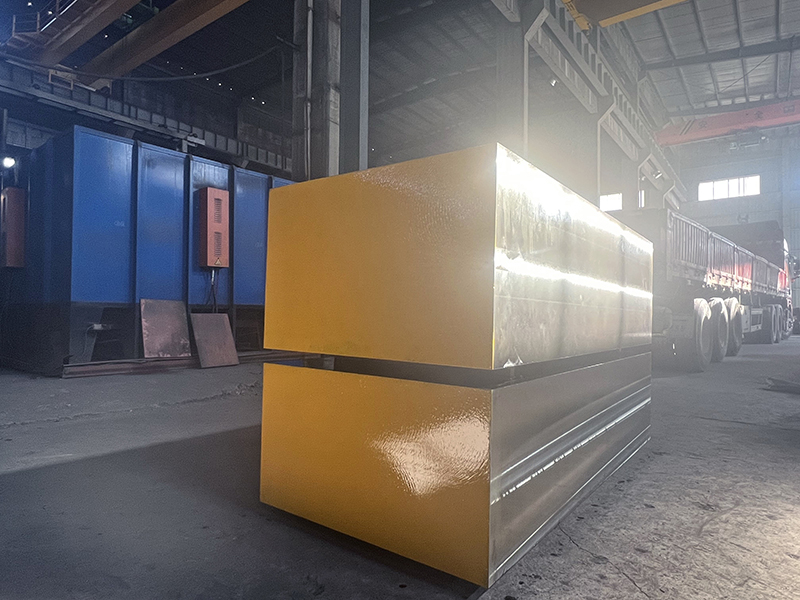

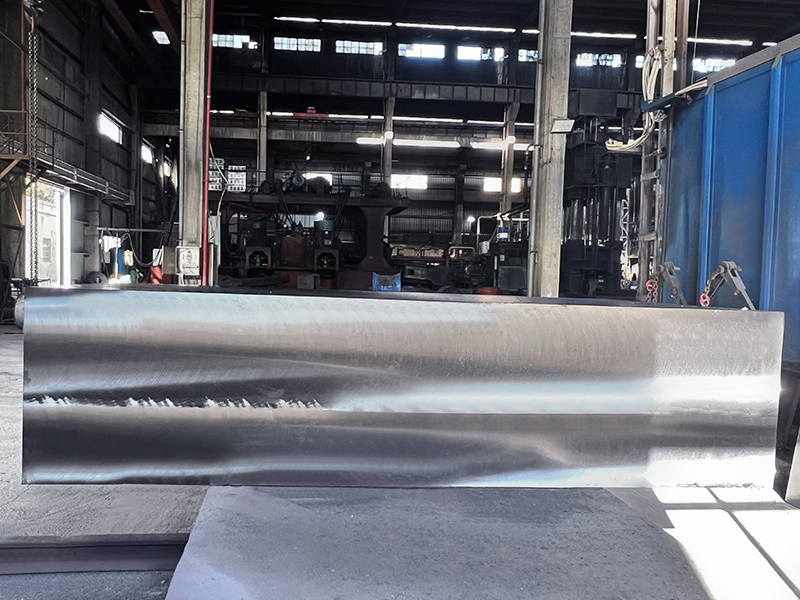

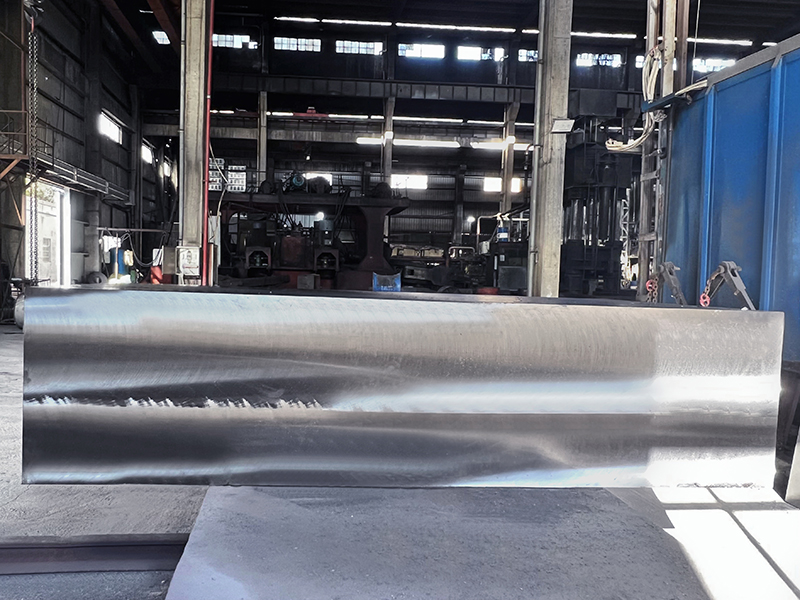

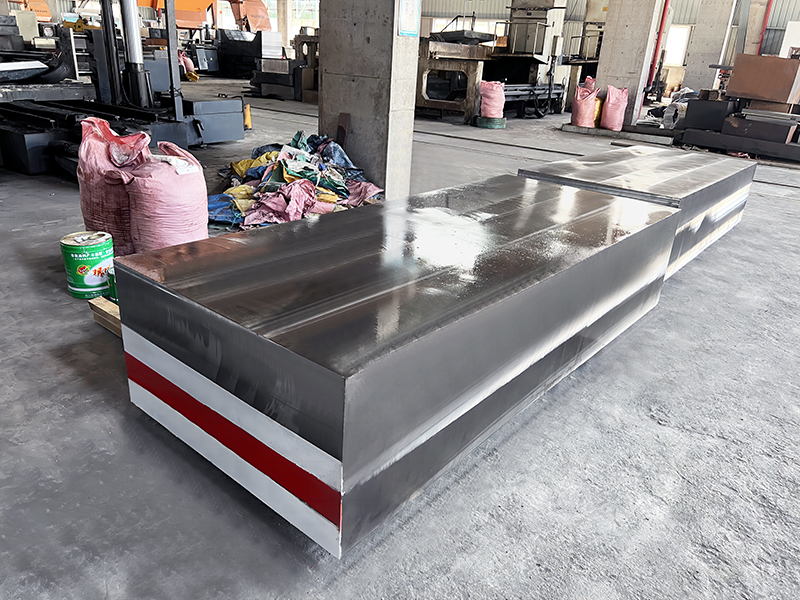

5CrNiMo Mould Steel

5CrNiMo mold steel characteristics

1.5CrNiMo has high strength. 5CrNiMo mold steel has excellent tensile strength and hardness and can withstand high pressure and severe deformation.

2.5CrNiMo has wear resistance. The steel has excellent wear resistance, keeping the knife sharp for a long time and extending its service life.

3.5CrNiMo has excellent corrosion resistance. 5CrNiMo mold steel has good corrosion resistance and can operate stably for a long time in harsh working environments.

4.5CrNiMo has high temperature stability. This steel can maintain excellent mechanical properties and stability in high temperature environments.

5.5CrNiMo is easy to process. 5CrNiMo mold steel has good forgeability and plasticity, making it easy for processing and mold manufacturing.

In short, 5CrNiMo is favored for its good toughness, strength, high wear resistance , processability and welding performance . The product can maintain its stability and reliability under long-term use and heavy load. This feature is particularly important for equipment and machinery that require long-term use and frequent operation.

description2

5CrNiM o mold steel application scope

1.Suitable for plastic molds, die-casting molds, stamping molds, hot pressing molds, and shaping molds;

2.Used to make small-section quenched and tempered parts that bear larger loads and large normalized parts with smaller stresses;

3.Suitable for manufacturing various large and medium- sized forging dies with complex shapes and large impact loads;

4.Used for manufacturing rollers, springs and mold frames requiring high strength.

Sanyao Company can provide customers with customized forging (including size, hardness, eye bolt, rough machining, quenching and tempering, rough surface grinding,fine surface grinding,etc.) to meet customers' individual needs.

Phone

Phone Send Email

Send Email