01

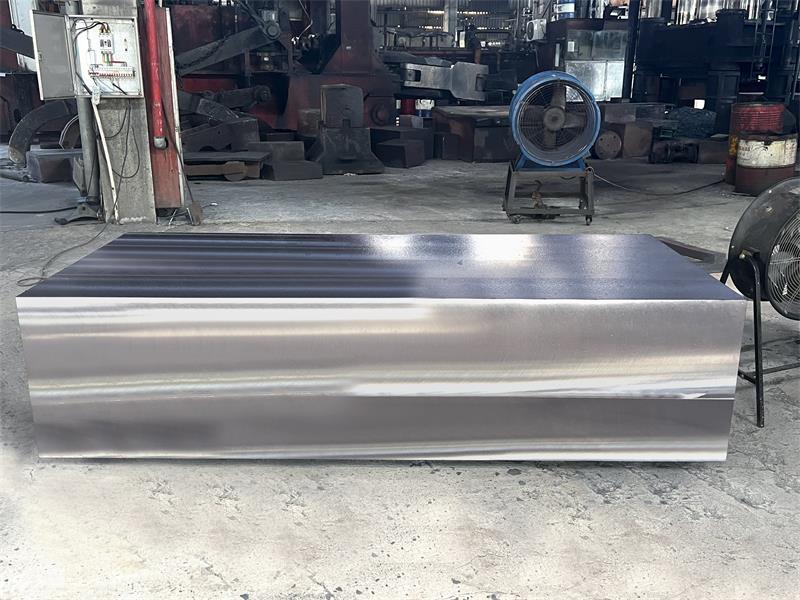

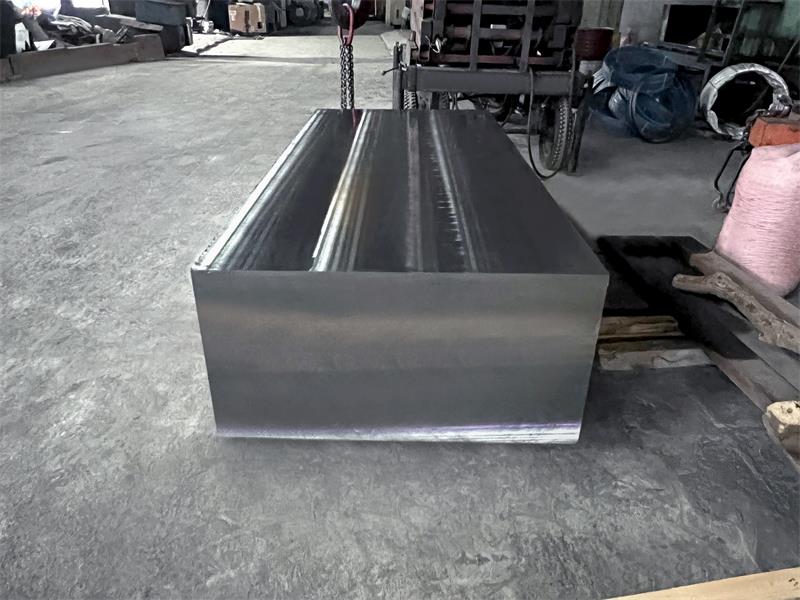

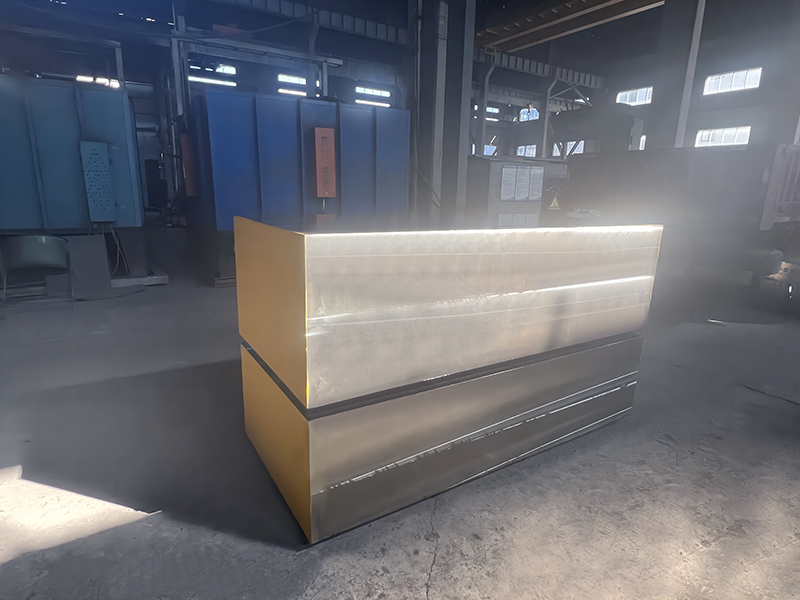

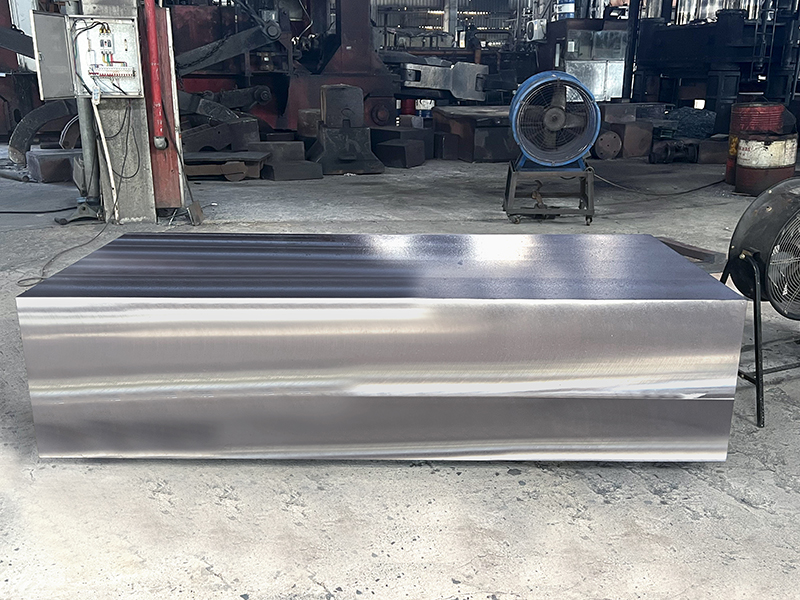

S50C Carbon Structural Steel

S50C carbon structural steel characteristics

1.The steel has a uniform metallographic structure and no structural defects.

2.This steel is a commonly used material for shaft parts. It is cheap. After quenching and tempering (or normalizing), it can obtain better cutting performance, and can also obtain higher strength, toughness and other comprehensive mechanical properties.

3.Because this kind of steel has good mechanical properties, it is often widely used in machinery manufacturing. But this is a medium carbon steel and its quenching performance is not good.

4.Medium-carbon high-strength carbon structural steel has high strength and hardness after quenching . The steel has medium machinability, low cold deformation plasticity, poor weldability, no temper brittleness during heat treatment, but low hardenability. And there is a tendency to crack during water quenching.

5.This steel is usually used after heat treatment such as normalizing or quenching and tempering, or high-frequency surface quenching .

6.Its strength and hardness are higher than S45C , but its plasticity and toughness are worse than S45C .

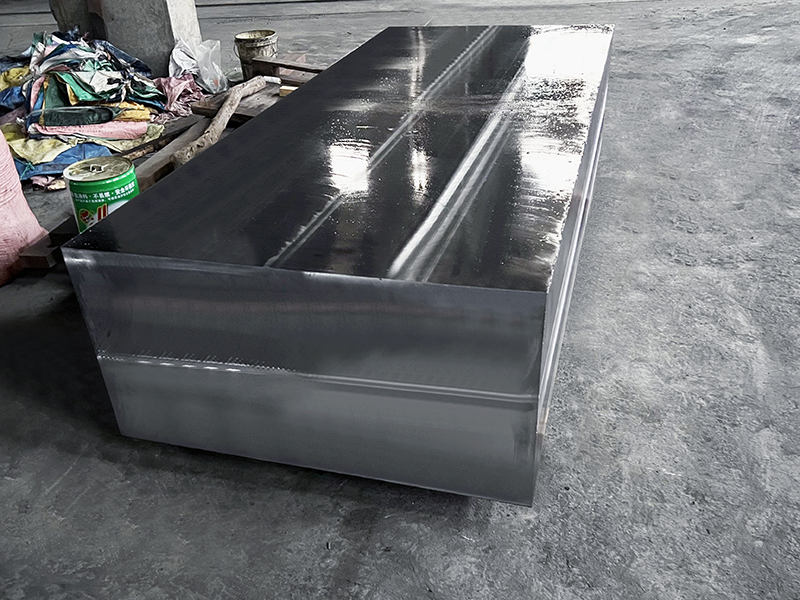

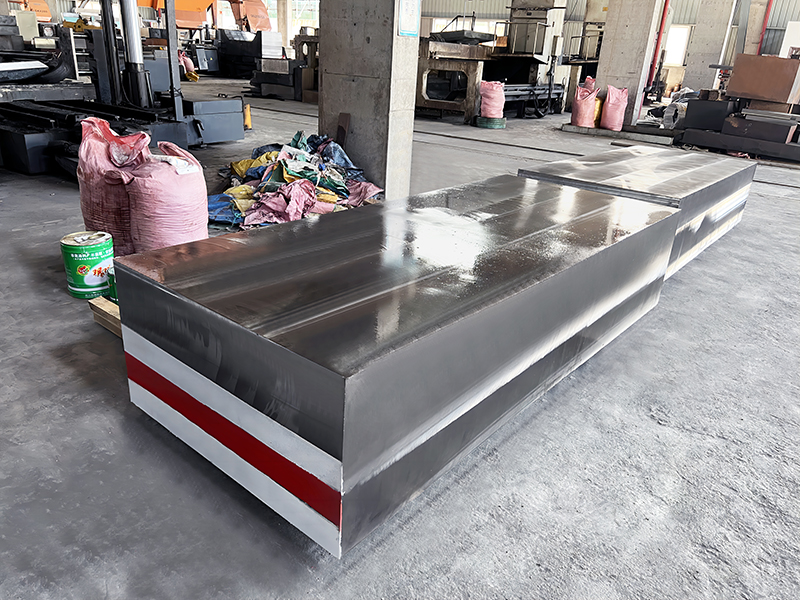

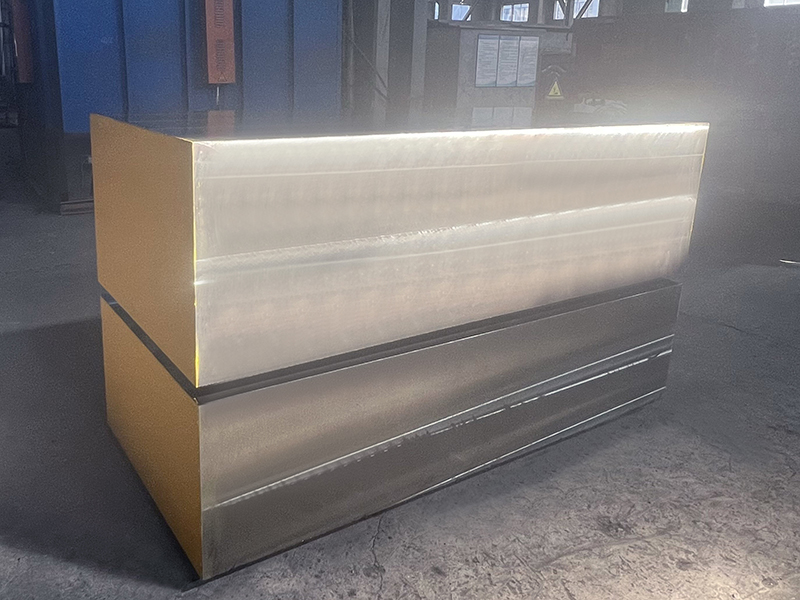

description2

Scope of application of S50C carbon structural steel

1.Suitable for manufacturing mechanical parts with low dynamic load, low impact load and good wear resistance, such as forged gears, shaft friction discs, machine tool spindles, engine spindles, rollers, tie rods, spring washers, etc.;

2.Suitable for manufacturing mold parts with high wear resistance requirements, large dynamic load and impact;

3.Used to manufacture parts in steam turbines that are not subject to great impact, such as crankshafts, main shafts, gears and mold frames, etc.

Sanyao Company can provide customers with customized forging (including size, hardness, eye bolt, rough machining, quenching and tempering, rough surface grinding,fine surface grinding,etc.) to meet customers' individual needs.

Phone

Phone Send Email

Send Email