0102030405

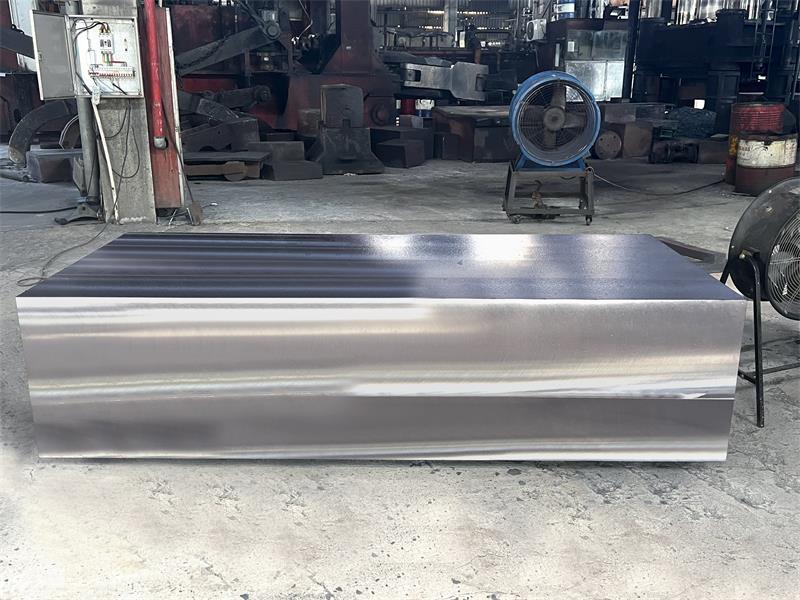

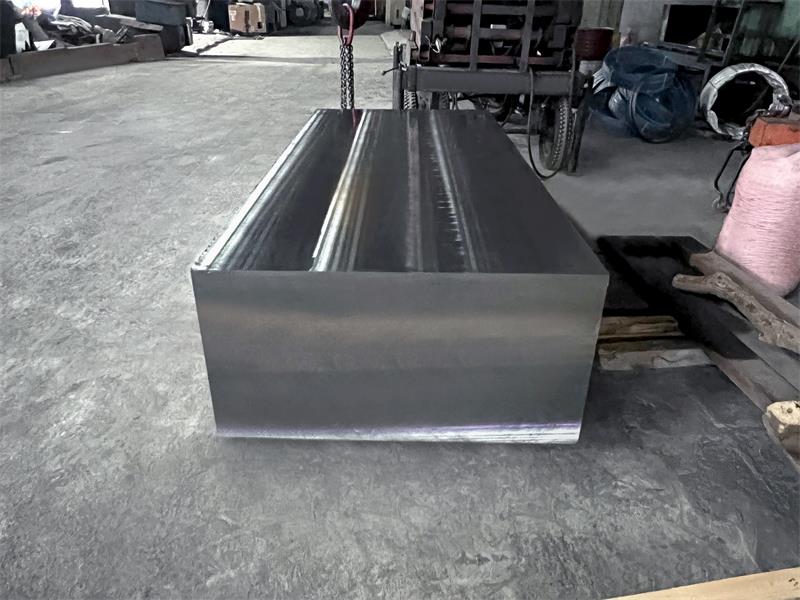

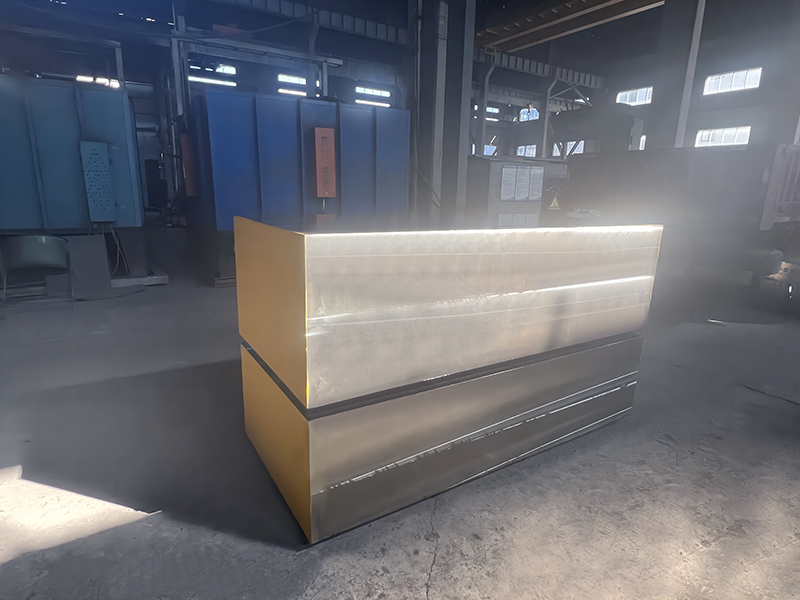

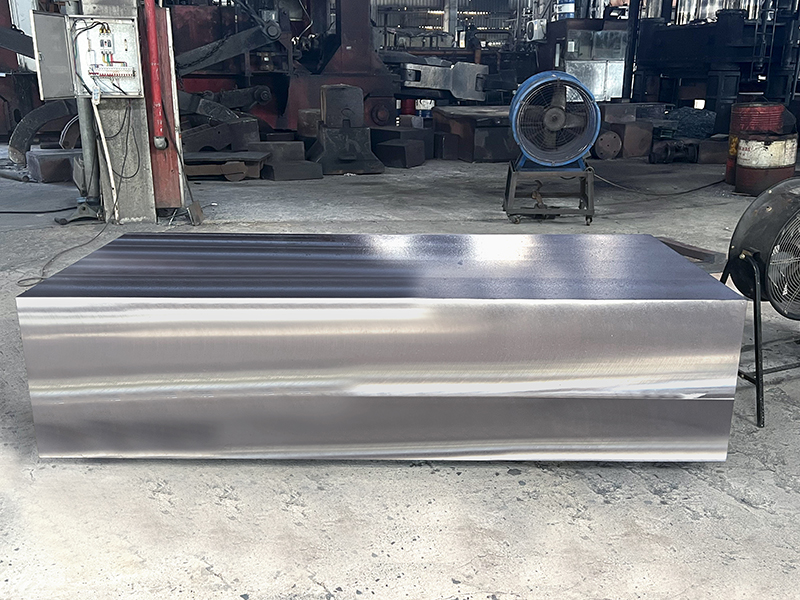

40Cr13 (4Cr13) Stainless Steel

40Cr13 (4Cr13) stainless steel characteristics

1. It is a stainless steel material with high hardness and high wear resistance.

2.Has good processing performance and mold performance. The excellent cutting performance of 40Cr13 stainless steel gives it excellent adaptability in various complex manufacturing processes, making it an ideal material for the production of knives and cutting tools.

3. It has high hardness and toughness after heat treatment and can be used to manufacture various tools and mechanical parts.

4. The hardness after quenching is generally above HRC48.

5. Has excellent corrosion resistance.

6. This steel has poor weldability, so care must be taken when using it . It is usually not used as a welded component.

The performance and use of 40Cr13 stainless steel are similar to that of 30Cr13 stainless steel, but its strength and hardness are higher than 30Cr13, and its toughness and corrosion resistance are slightly lower.

description2

40Cr13 (4Cr13) stainless steel application scope

1.Used to manufacture parts and molds with higher requirements than 30Cr13;

2.Can be used as stamping mold accessories and templates;

3.Suitable for making high mirror surface and high precision injection mold core cavity;

4.Suitable for scenes with high temperature rust and anti-corrosion;

5.Can be used to make knives, molds and mechanical parts, such as scissors, screwdrivers, blades, bearings, etc.;

6.Can be used to manufacture industrial equipment and automotive parts to meet high strength and wear resistance requirements;

7.It is widely used in daily life, such as kitchen knives, household items and medical equipment.

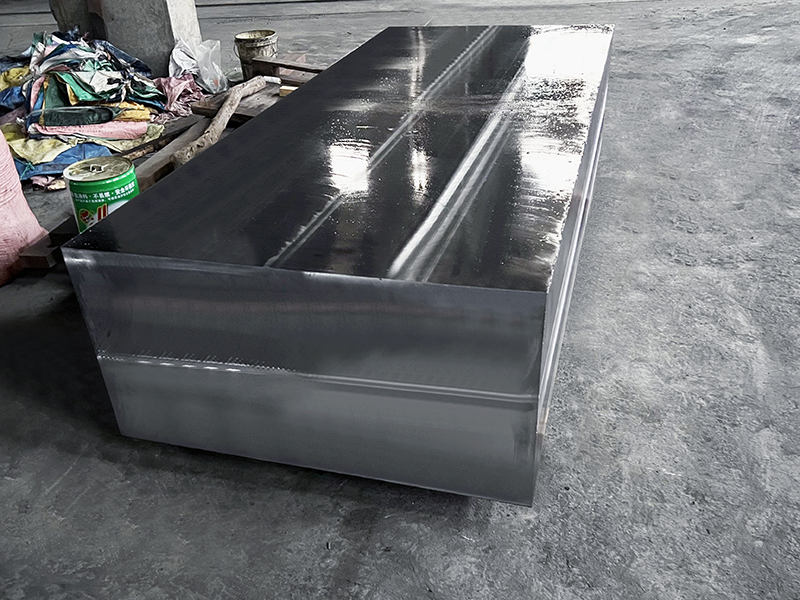

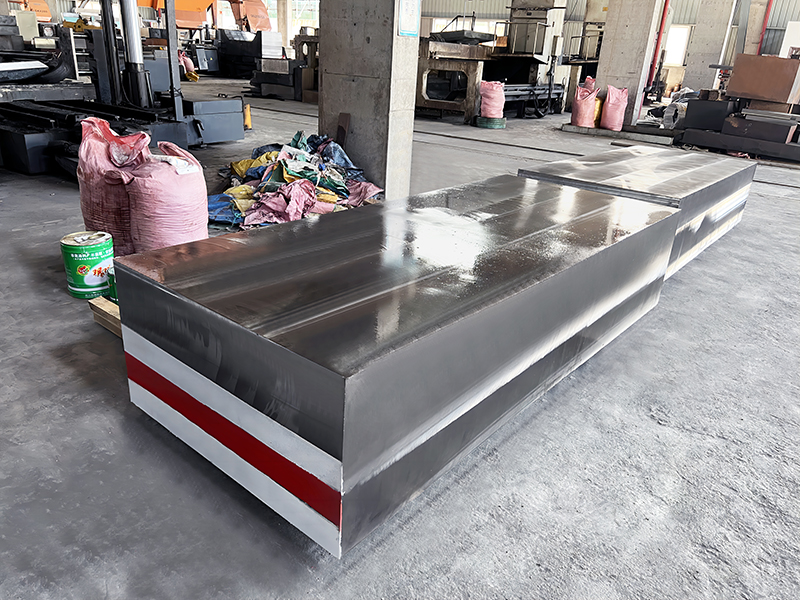

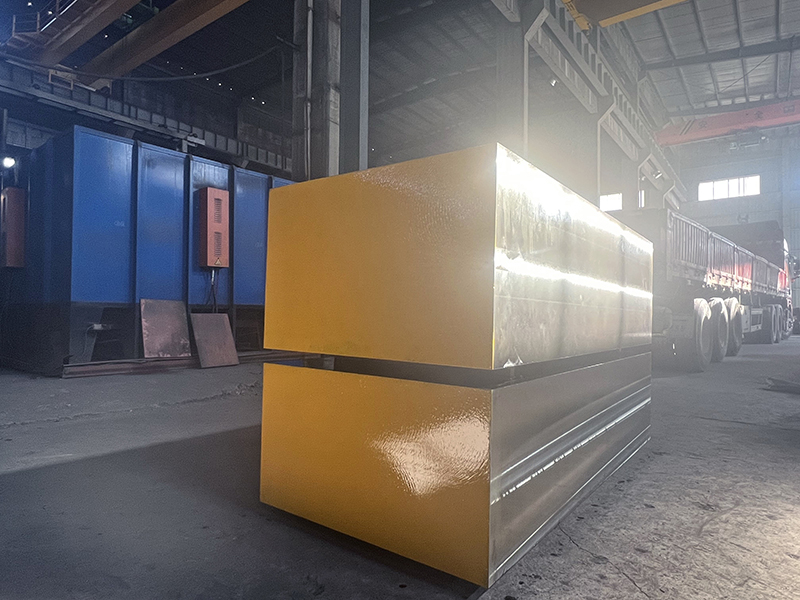

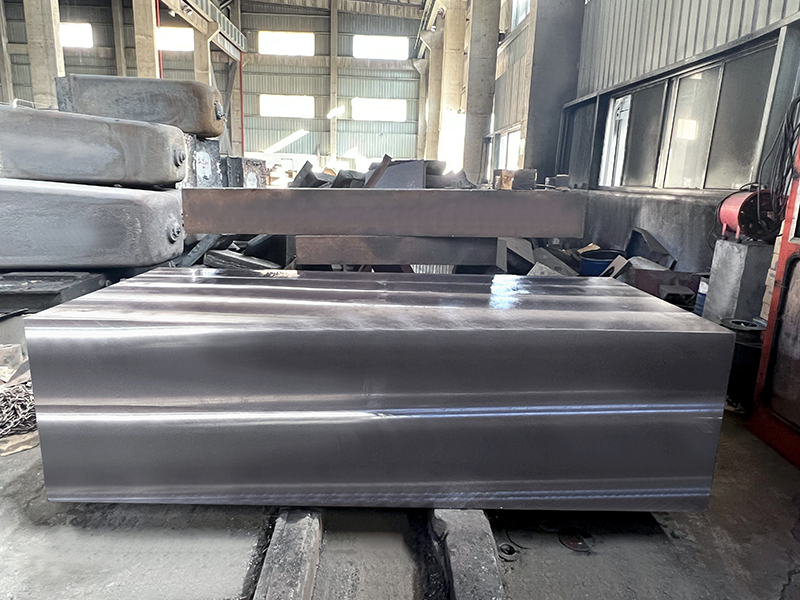

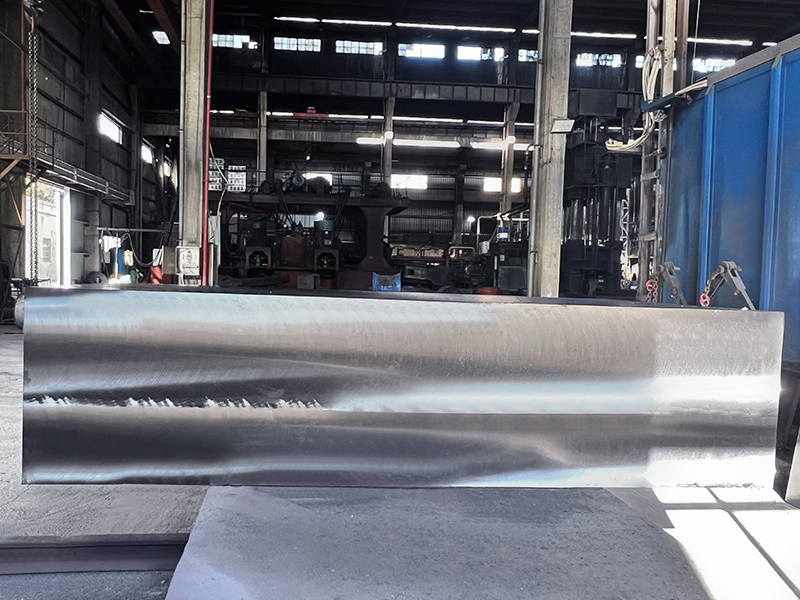

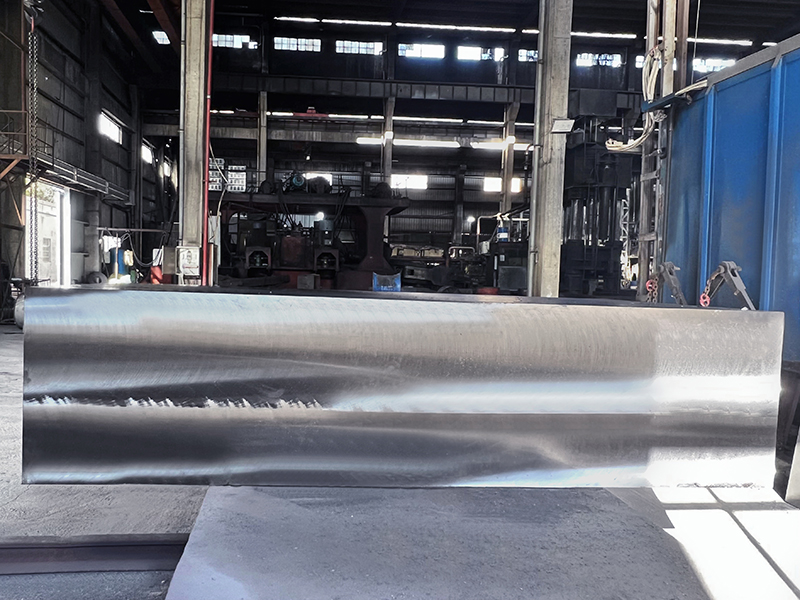

Sanyao Company can provide customers with customized forging (including size, hardness, eye bolt, rough machining, quenching and tempering, rough surface grinding,fine surface grinding,etc.) to meet customers' individual needs.

Phone

Phone Send Email

Send Email