0102

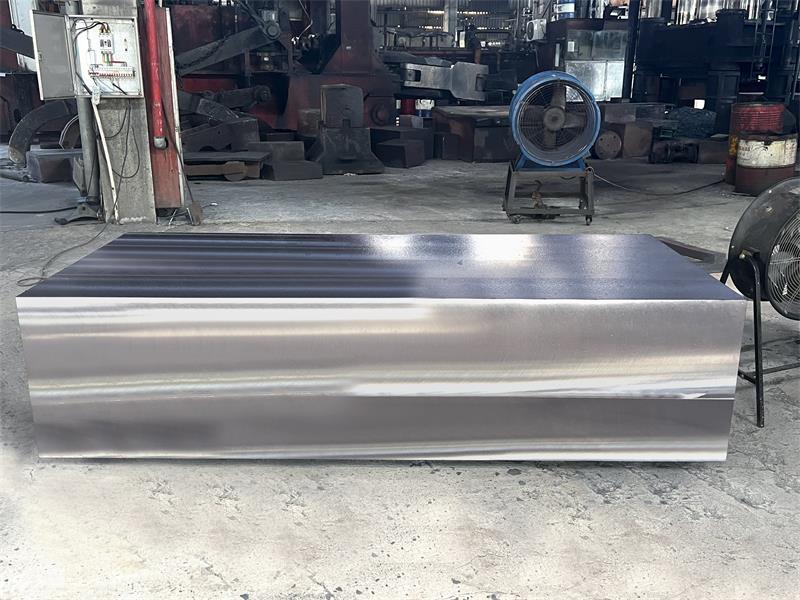

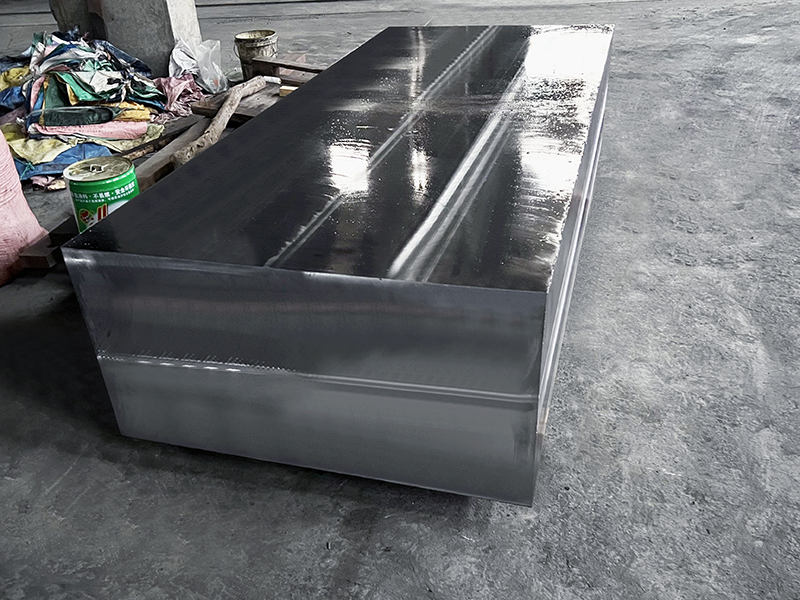

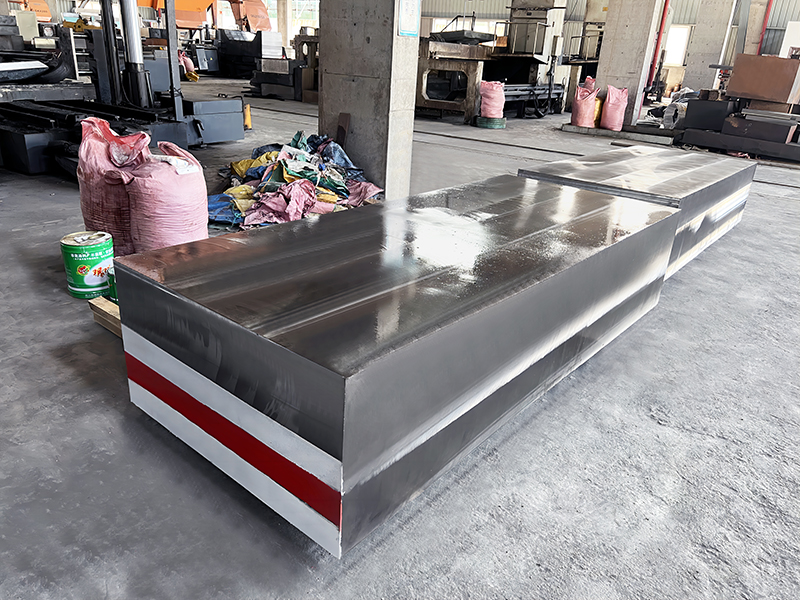

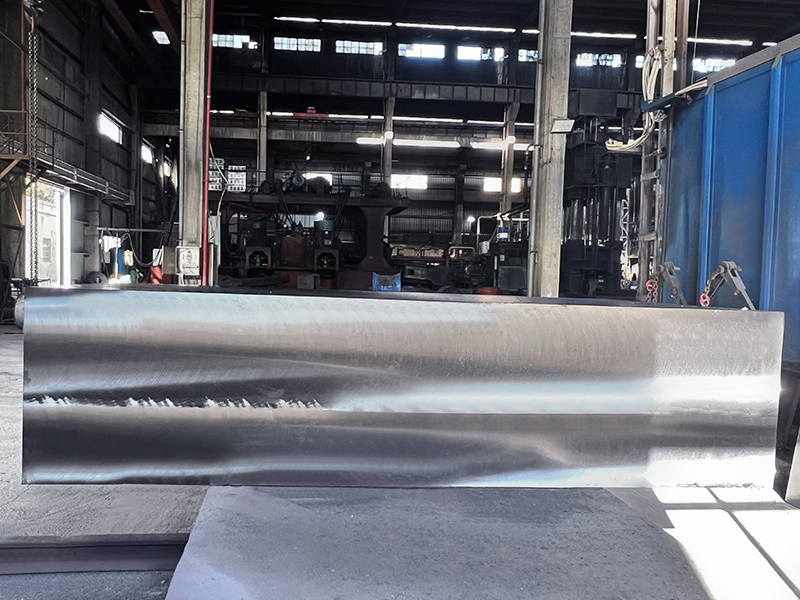

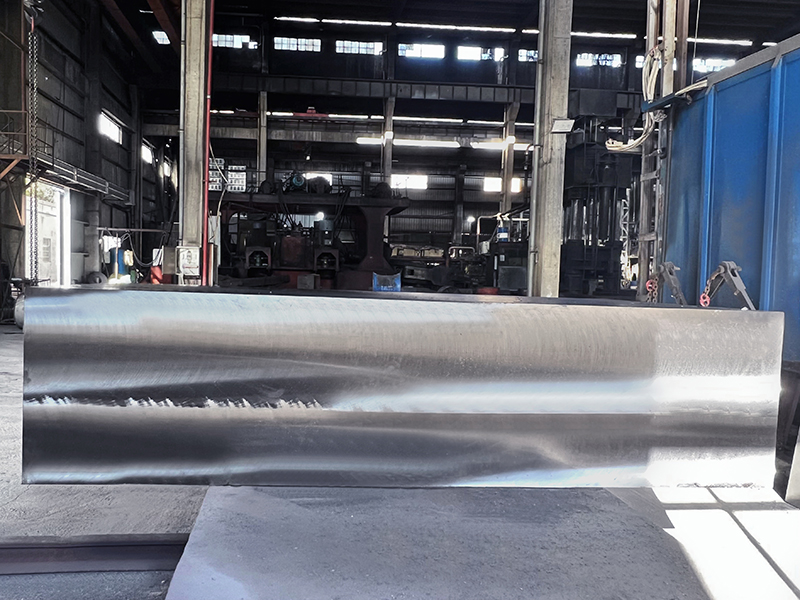

S55C Carbon Structural Steel

S55C carbon structural steel characteristics

1.The steel has a uniform metallographic structure and no structural defects.

2.This steel is cheap and easy to process, and is suitable for surface hardening treatments such as high-frequency quenching and flame quenching. This steel contains carbon (mass fraction ≥ 0.4% ) and has excellent wear resistance, but its ductility is reduced and it is easy to deform and crack after quenching. Therefore, quenching is extremely important, and it must be cooled quickly after tempering to avoid temper brittleness.

3.This steel is a high-strength medium-carbon steel. It has high surface hardness and strength after treatment, but has poor plasticity and toughness, medium cutting performance, poor weldability and hardenability, and water quenching has a tendency to form cracks.

4.Harder than S50C, with higher strength and better elasticity, but worse plasticity and toughness than S45C.

description2

Scope of application of S55C carbon structural steel

1.Can be used as backing plates for various cold work molds ; drilling mold fixing plates ; standard formwork materials, etc.;

2.Generally used after normalizing or quenching, it is used for parts that require high strength and wear resistance or elasticity, dynamic load and small impact load, such as gears, rims, flat springs, crankshafts, etc., and can also be used as casting;

3.Used to manufacture mold frames and parts that require high strength and hardness, dynamic loads, and small impact forces, such as shafts, friction discs, rollers, gears, etc.

Sanyao Company can provide customers with customized forging (including size, hardness, eye bolt, rough machining, quenching and tempering, rough surface grinding,fine surface grinding,etc.) to meet customers' individual needs.

Phone

Phone Send Email

Send Email