0102030405

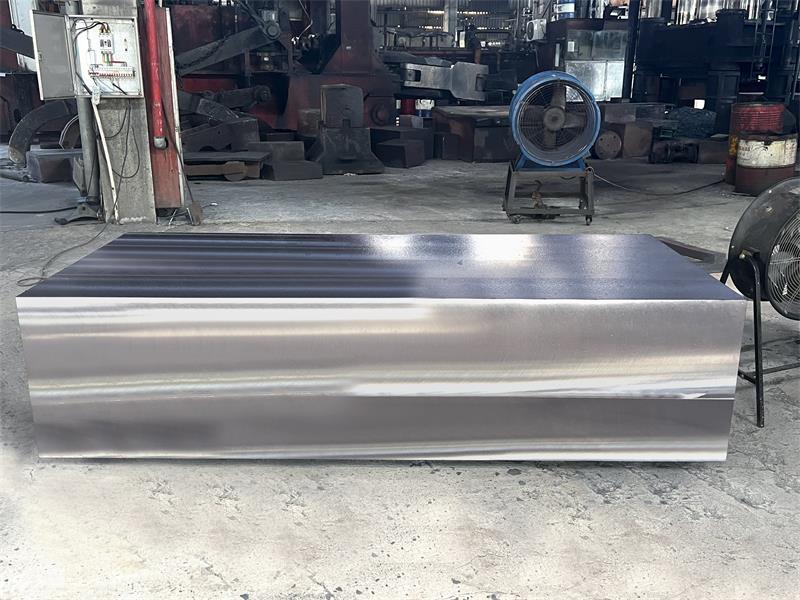

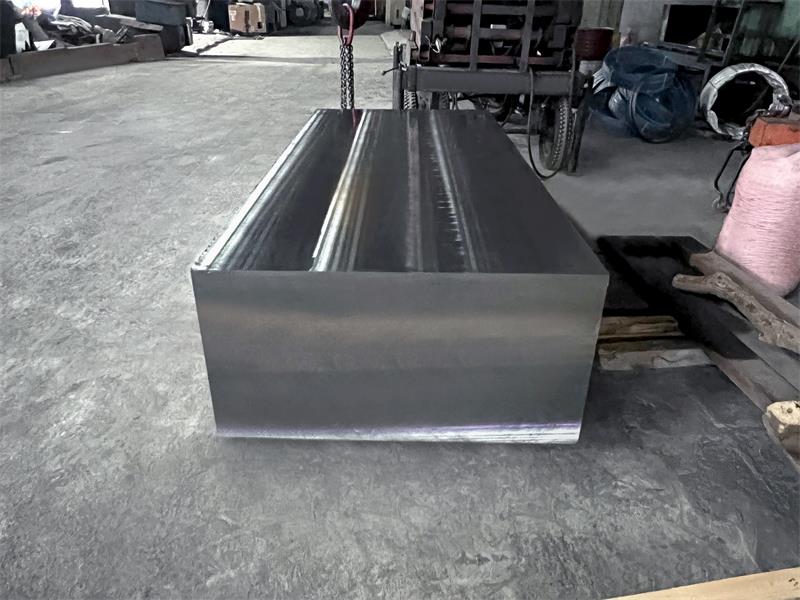

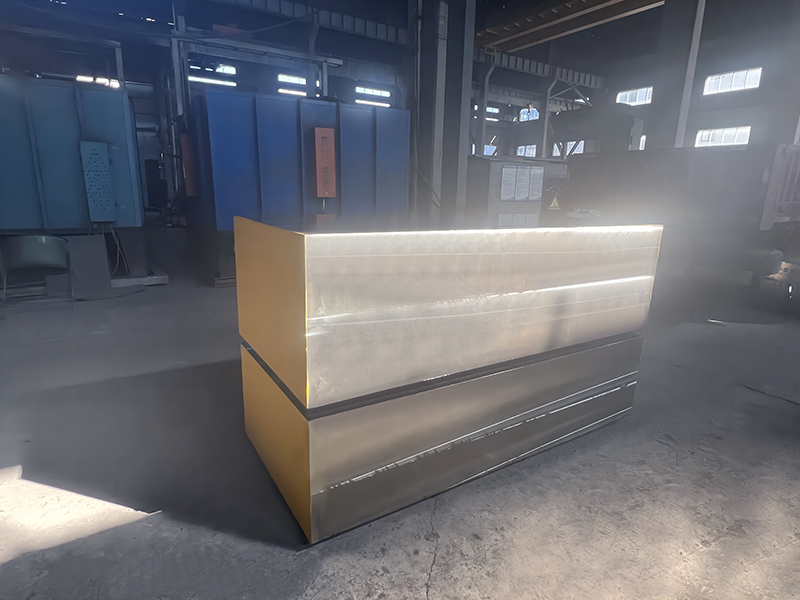

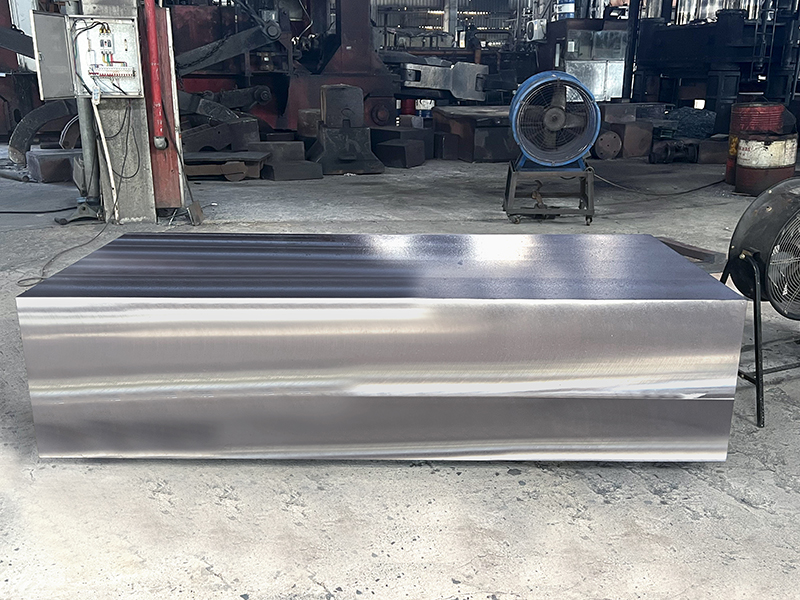

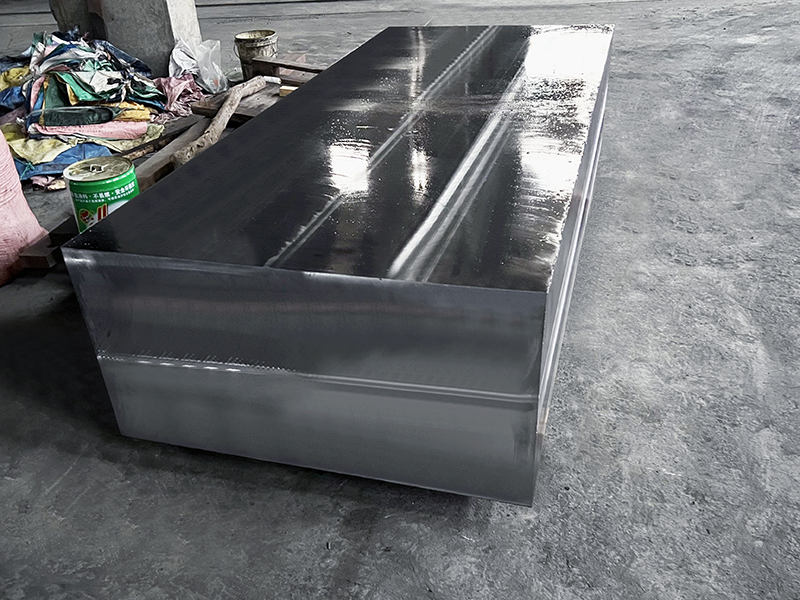

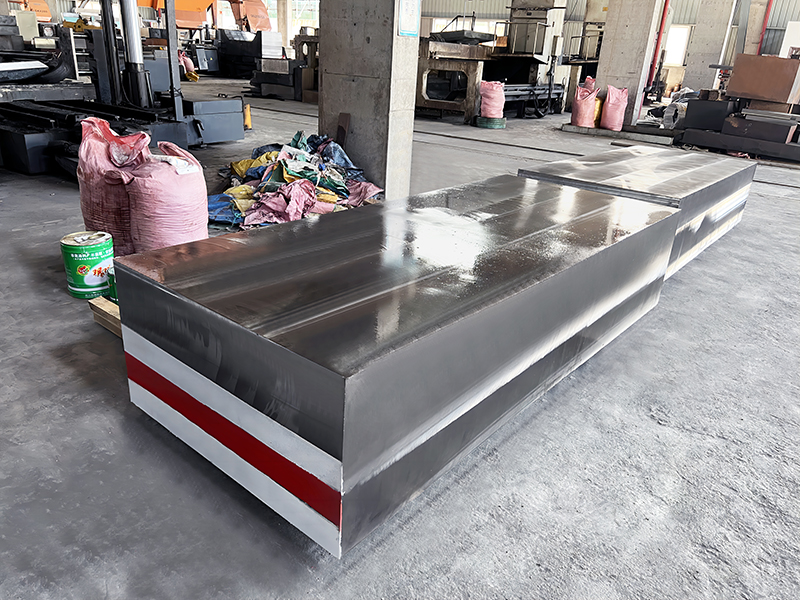

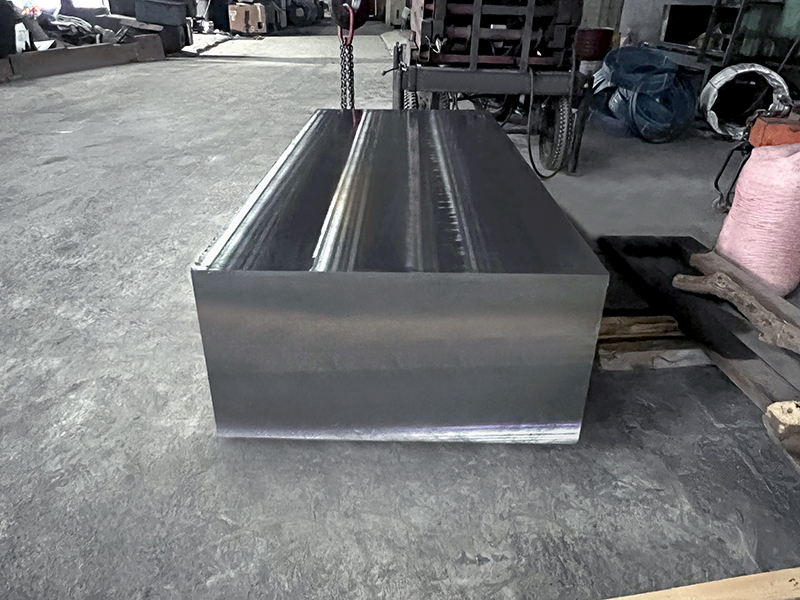

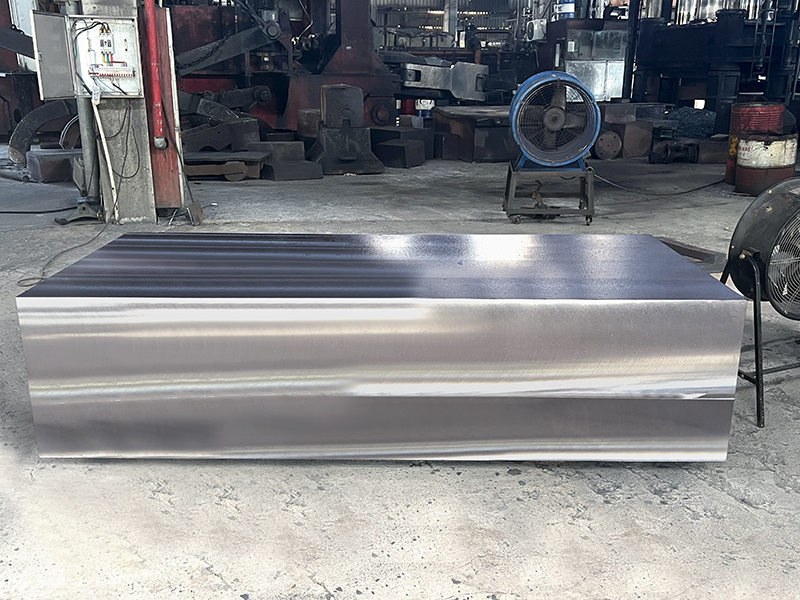

3Cr2W8V Mould Steel

3Cr2W8V alloy tool steel characteristics

1.The addition of Chromium element improves the hardness and corrosion resistance of this steel, so that it can maintain stable performance in high temperature and corrosion environment; The addition of Tungsten improves the hardness and wear resistance of steel, making it suitable for high strength and high wear working environment; The addition of Vanadium element improves the strength and toughness of steel and makes it have good impact resistance.

2. Its excellent processing properties also make 3Cr2W8V one of the preferred materials in the field of mold manufacturing.

3. Although it has poor cold and heat fatigue resistance, it is easy to have cold and heat fatigue cracks and failure under acute heat and acute cooling conditions, and is not suitable for working under acute cooling and acute heat conditions, its tempering resistance is high, and it can still be used as a high heat strength hot work die steel in many hot processing fields.

2. Its excellent processing properties also make 3Cr2W8V one of the preferred materials in the field of mold manufacturing.

3. Although it has poor cold and heat fatigue resistance, it is easy to have cold and heat fatigue cracks and failure under acute heat and acute cooling conditions, and is not suitable for working under acute cooling and acute heat conditions, its tempering resistance is high, and it can still be used as a high heat strength hot work die steel in many hot processing fields.

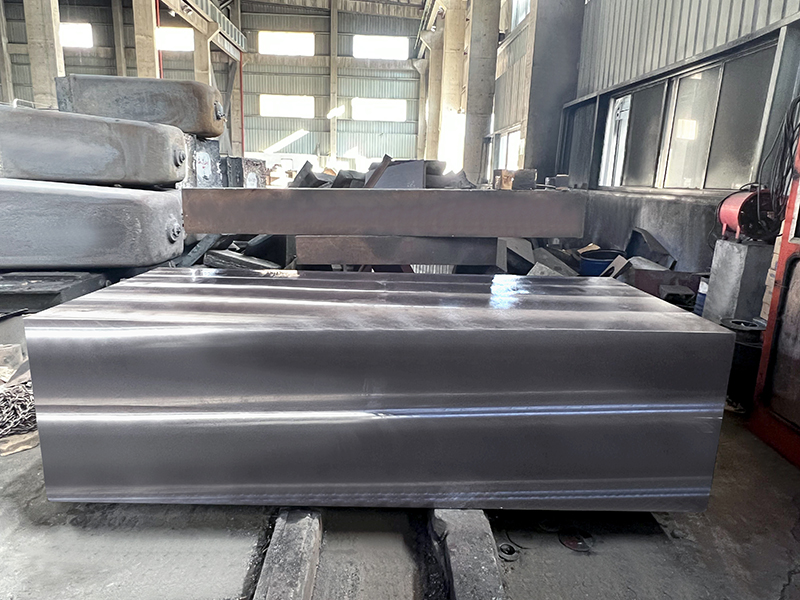

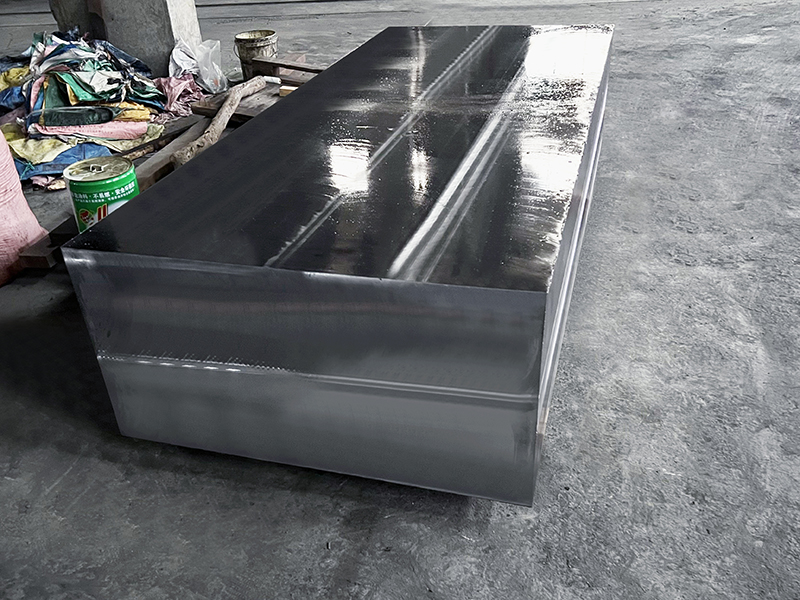

description2

Scope of application of 3Cr2W8V alloy tool steel

1.Widely used in mold manufacturing, machining and automobile manufacturing and other fields.

2.In the field of mold manufacturing, 3Cr2W8V is widely used in the manufacture of plastic molds, die casting molds and hot work molds. Due to its excellent wear resistance and corrosion resistance, 3Cr2W8V molds can withstand high-intensity working environments and maintain long-term stable performance.

3.In the field of machining, 3Cr2W8V is often used to manufacture tools, punches and molds. Due to its high hardness and wear resistance, tools made of 3Cr2W8V can maintain stable cutting performance in high-speed cutting and heavy duty cutting, greatly improving processing efficiency and product quality. At the same time, its excellent wear resistance also extends the service life of the tool and reduces the cost of replacement and maintenance.

4.In the field of automobile manufacturing, 3Cr2W8V is often used to manufacture engine parts, transmission parts and chassis parts. Because auto parts need to withstand high temperature, high pressure and high speed working environment, the performance requirements of materials are very high. 3Cr2W8V has excellent high temperature resistance and wear resistance, which can meet the harsh requirements of automotive parts for material properties and ensure the safety and reliability of automobiles.

Sanyao Company can provide customers with customized forging (including size, hardness, eye bolt, rough machining, quenching and tempering, rough surface grinding,fine surface grinding,etc.) to meet customers' individual needs.

2.In the field of mold manufacturing, 3Cr2W8V is widely used in the manufacture of plastic molds, die casting molds and hot work molds. Due to its excellent wear resistance and corrosion resistance, 3Cr2W8V molds can withstand high-intensity working environments and maintain long-term stable performance.

3.In the field of machining, 3Cr2W8V is often used to manufacture tools, punches and molds. Due to its high hardness and wear resistance, tools made of 3Cr2W8V can maintain stable cutting performance in high-speed cutting and heavy duty cutting, greatly improving processing efficiency and product quality. At the same time, its excellent wear resistance also extends the service life of the tool and reduces the cost of replacement and maintenance.

4.In the field of automobile manufacturing, 3Cr2W8V is often used to manufacture engine parts, transmission parts and chassis parts. Because auto parts need to withstand high temperature, high pressure and high speed working environment, the performance requirements of materials are very high. 3Cr2W8V has excellent high temperature resistance and wear resistance, which can meet the harsh requirements of automotive parts for material properties and ensure the safety and reliability of automobiles.

Sanyao Company can provide customers with customized forging (including size, hardness, eye bolt, rough machining, quenching and tempering, rough surface grinding,fine surface grinding,etc.) to meet customers' individual needs.

Phone

Phone Send Email

Send Email