010203

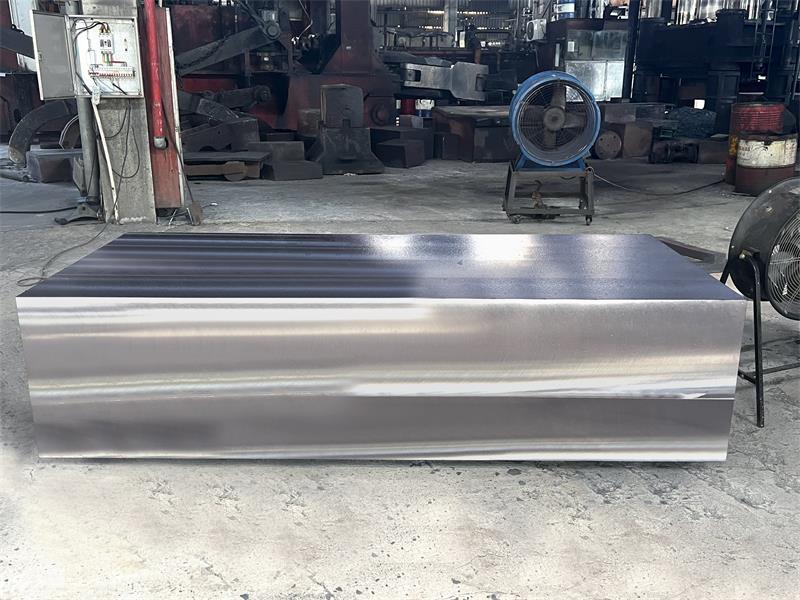

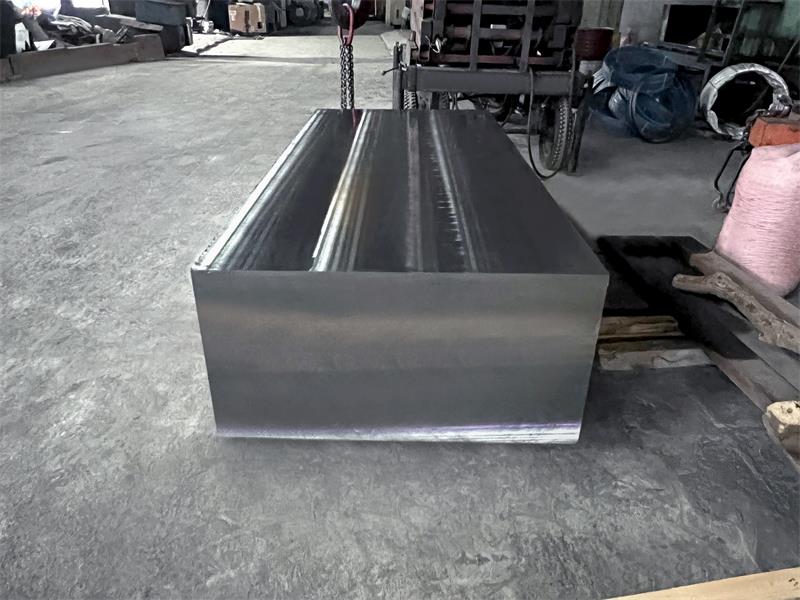

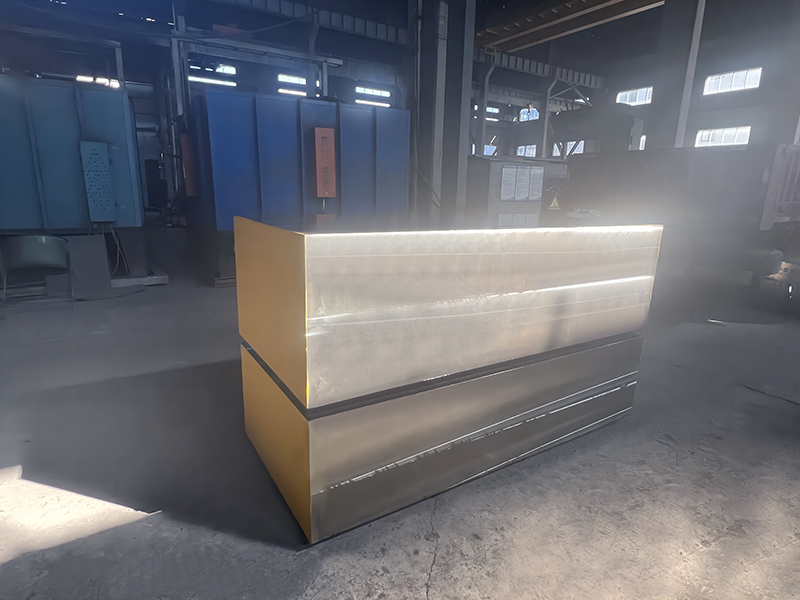

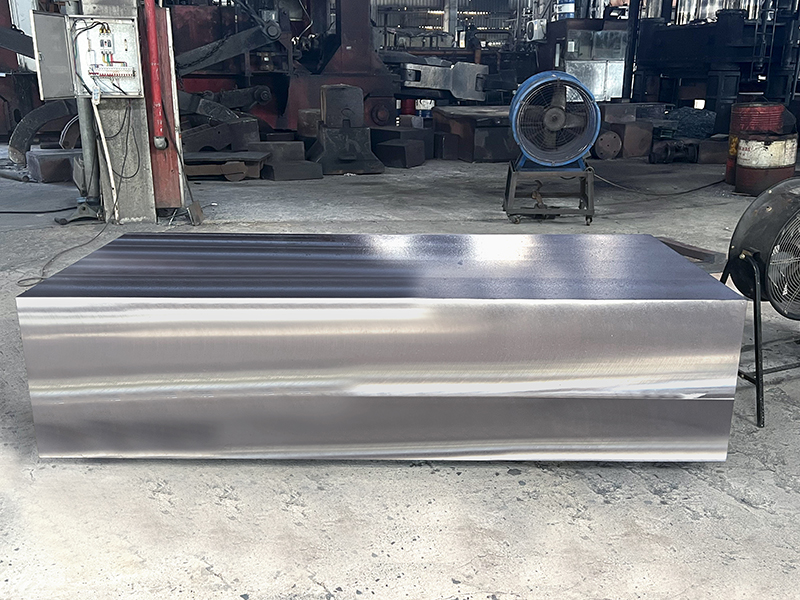

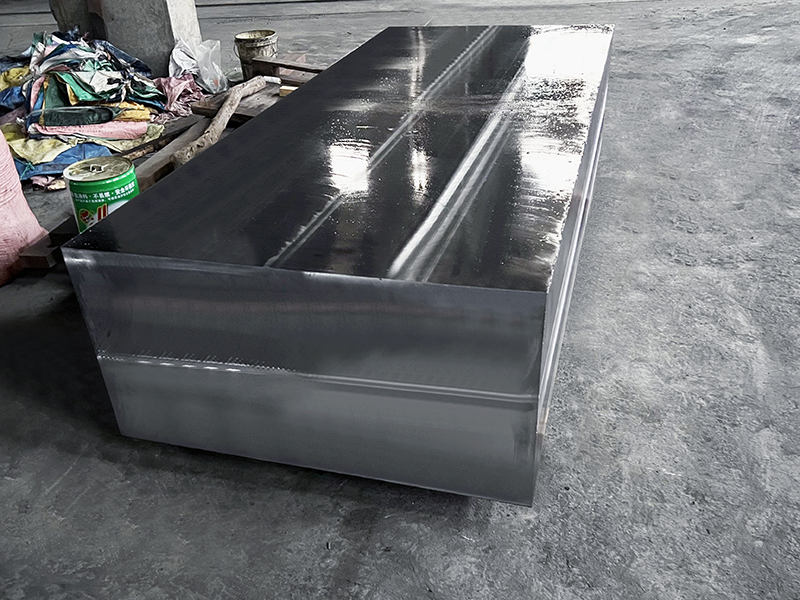

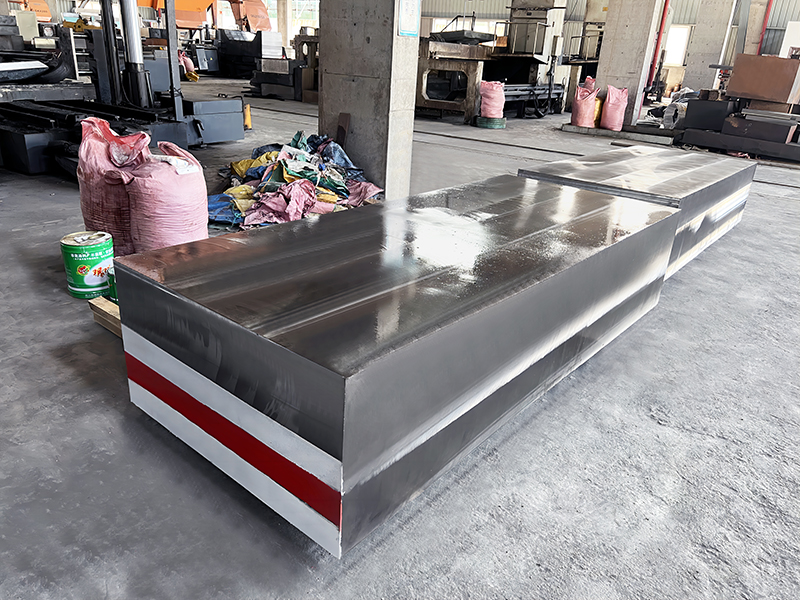

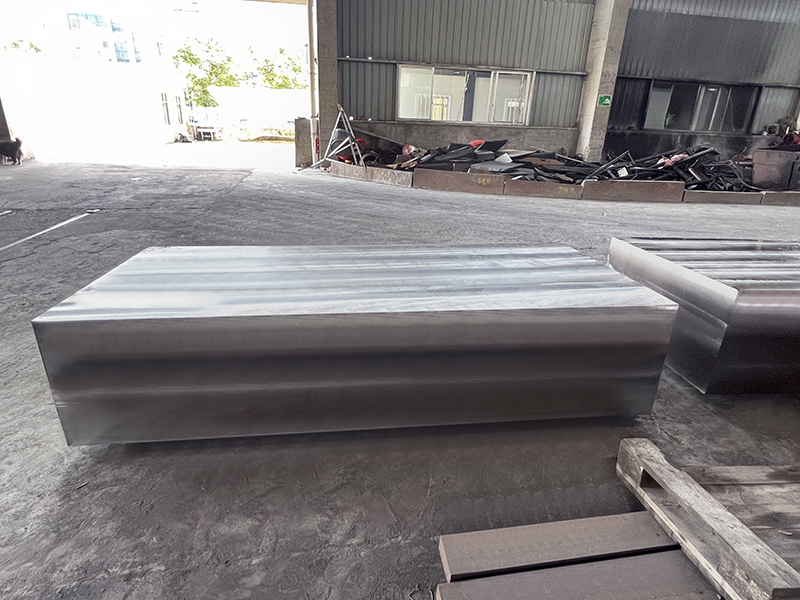

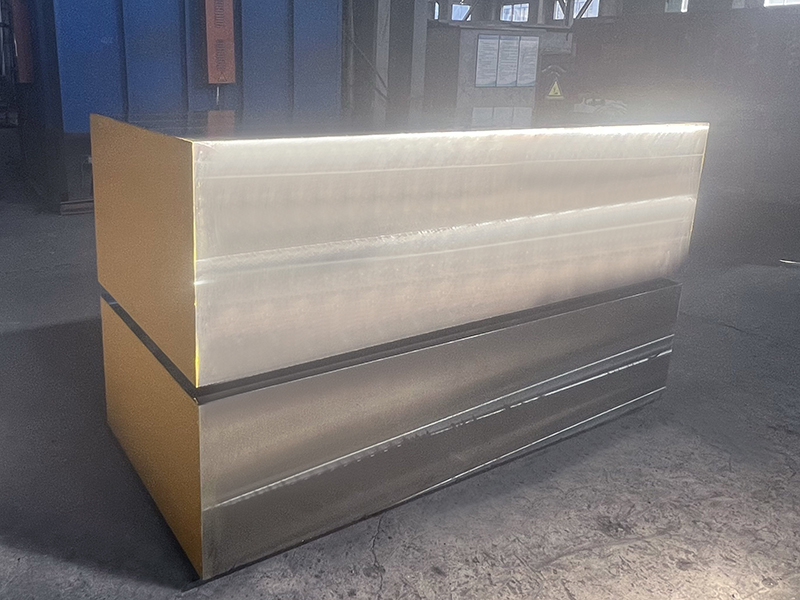

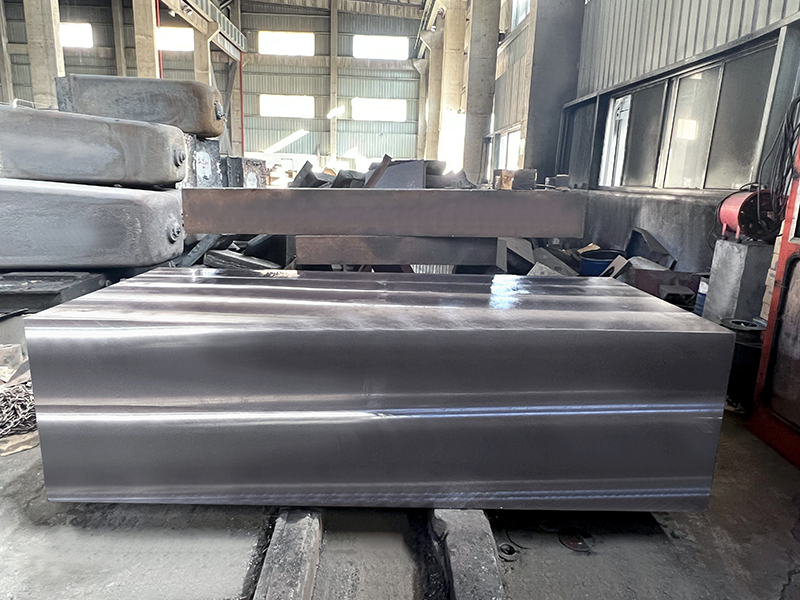

40Cr/ SCr440 Alloy Structural Steel

40Cr alloy structural steel characteristics

1.The tensile strength, yield strength and hardenability of 40Cr alloy structural steel are higher than those of 40 steel, but the welding performance is relatively limited and has a tendency to form cracks.

2.It has good comprehensive properties of plasticity, toughness and strength, and has the best comprehensive mechanical properties. It is one of the most widely used steels in the machinery manufacturing industry.

3.The steel is moderately priced and easy to process. It can obtain certain toughness, plasticity and wear resistance after appropriate heat treatment. Normalizing can promote tissue refinement, approach a balanced state, and improve the cutting performance of the blank.

4.The main role of Cr in heat treatment is to improve the hardenability of steel. Therefore, 40Cr steel has good hardenability. After quenching (or quenching and tempering) treatment, the mechanical properties such as strength, hardness, impact toughness and so on of 40Cr are also significantly higher than that of No. 45 steel. However, due to its strong hardenability, the internal stress of 40Cr is greater than that of No. 45 steel during quenching. Under the same conditions, the cracking tendency of 40Cr material is greater than that of No. 45 steel material, so stress relief treatment is required.

description2

Scope of application of 40Cr alloy structural steel

1.Used to manufacture molds with higher requirements than P20;

2.After quenching and tempering, this kind of steel is used to manufacture mechanical parts that bear medium loads and work at medium speeds, such as steering knuckles, rear half shafts of automobiles, and gears, shafts, worms, spline shafts, center sleeves, etc. on machine tools;

3.After quenching and medium-temperature tempering, it is used to manufacture parts that withstand high load, impact and medium-speed operation, such as gears, spindles, oil pump rotors, sliders, collars, etc.;

4.40Cr alloy structural steel is suitable for medium-precision and high-speed shaft parts. This type of steel has good comprehensive mechanical properties after tempering and quenching.

Sanyao Company can provide customers with customized forging (including size, hardness, eye bolt, rough machining, quenching and tempering, rough surface grinding,fine surface grinding,etc.) to meet customers' individual needs.

Phone

Phone Send Email

Send Email