0102030405

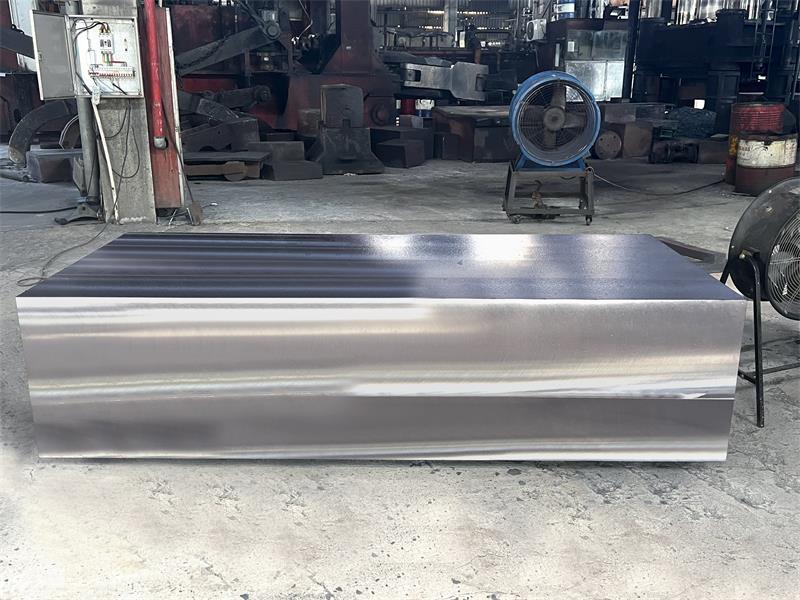

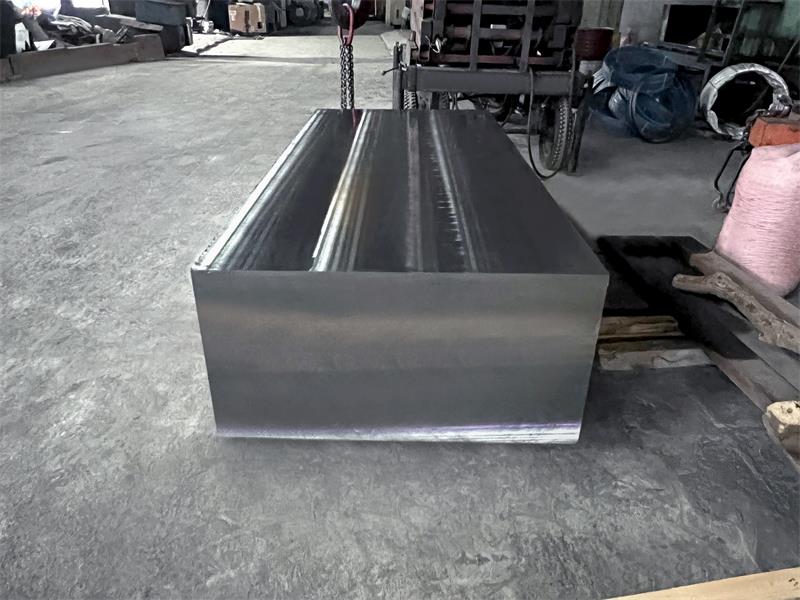

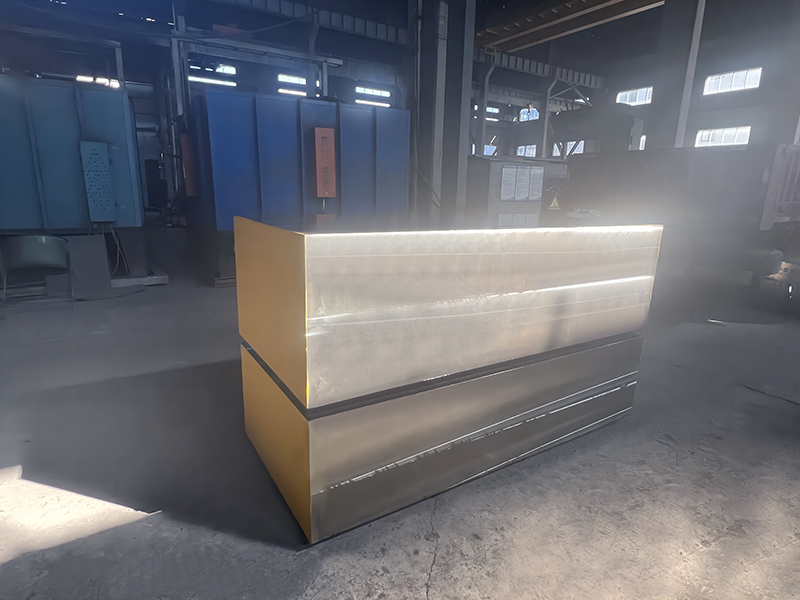

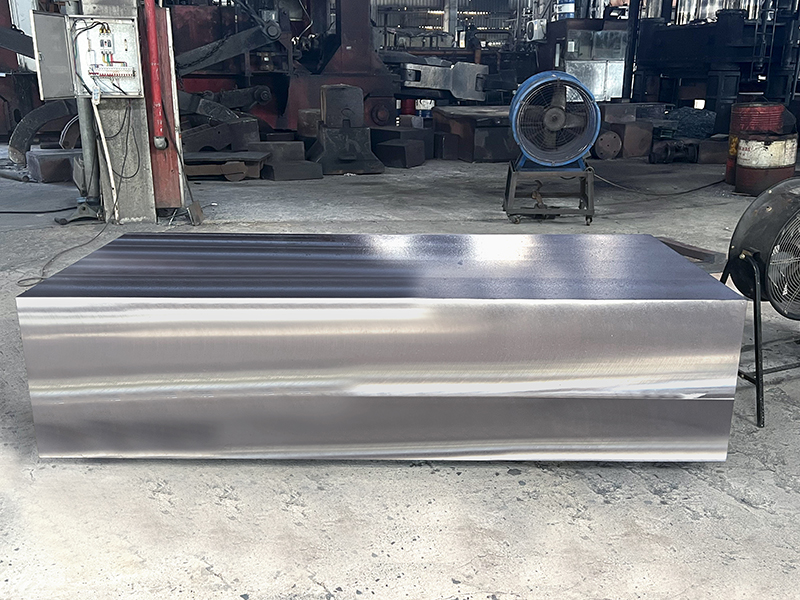

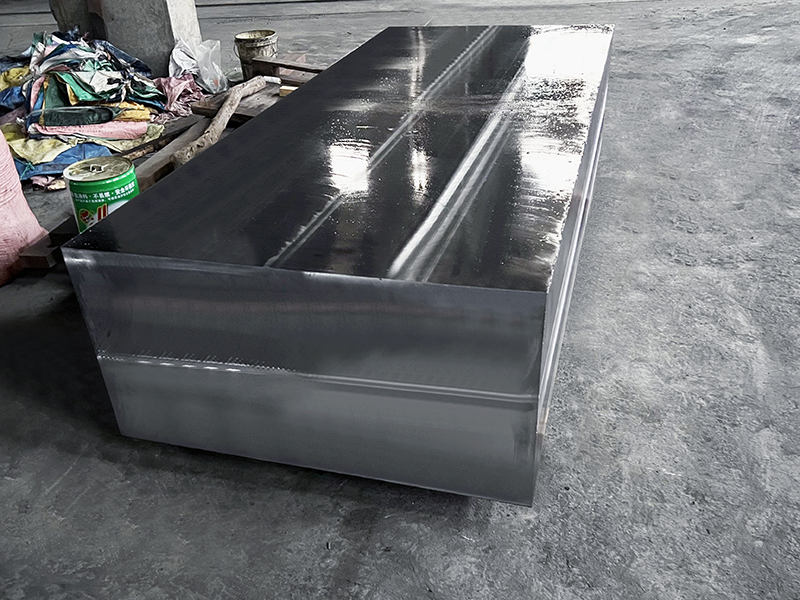

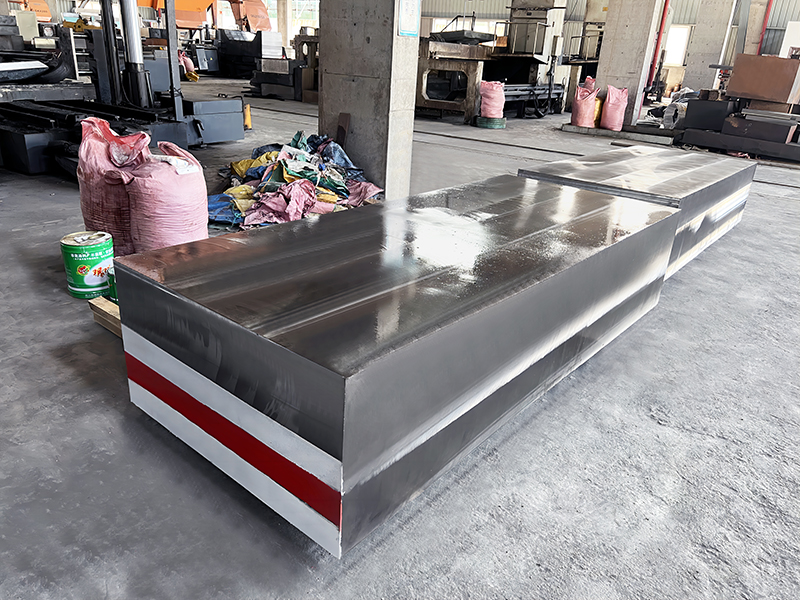

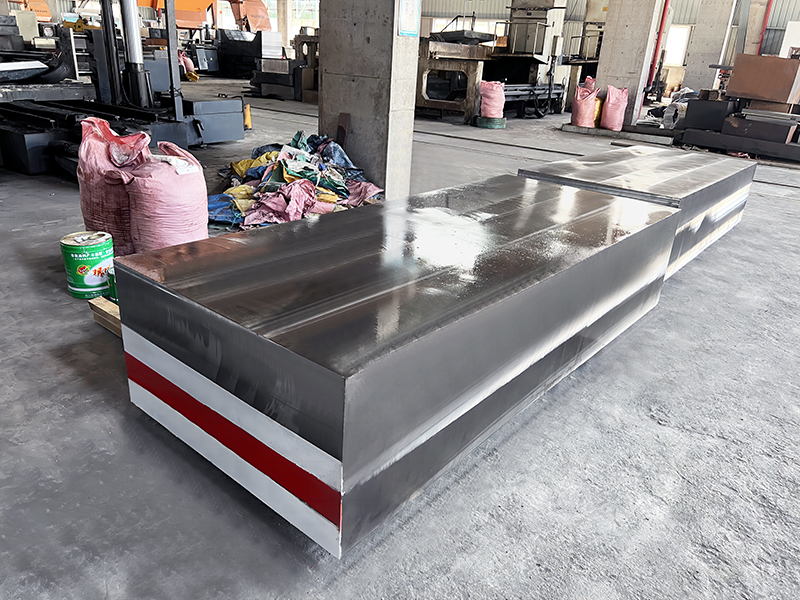

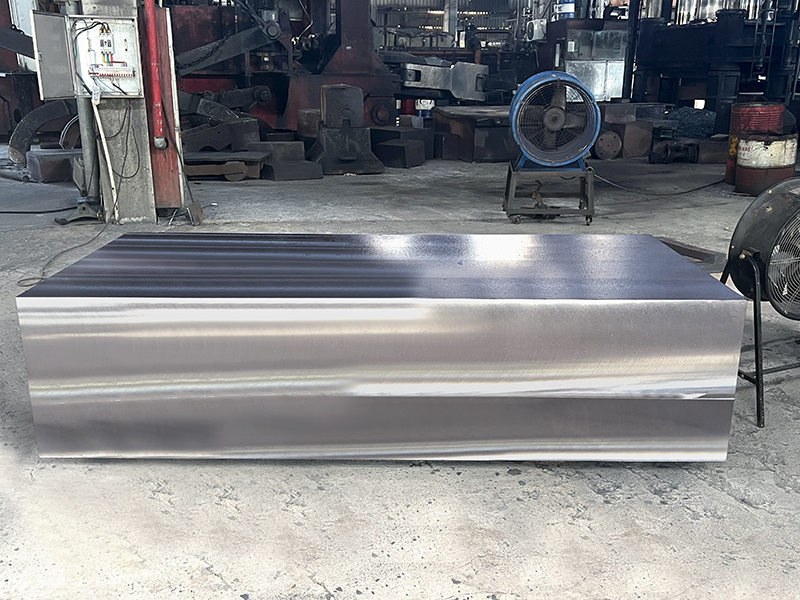

35CrMo/1.7220 Alloy Structural Steel

35CrMo alloy structural steel characteristics

1.It has high static strength, impact toughness and high fatigue limit, and its hardenability is higher than 40Cr.

2.It has high creep strength and lasting strength at high temperature, and the long-term working temperature can reach 500℃. During cold deformation, the plasticity is medium, the weldability is poor. Low temperature to -110 degrees Celsius, it has high static strength, impact toughness and high fatigue strength, good hardenability, no tendency to overheat, small quenching deformation, good cold deformation plasticity,medium cutting workability , however, there is the first type of tempering brittleness, poor weldability, preheating to 150~400 degrees Celsius before welding, post-welding heat treatment to eliminate stress, generally used after tempering treatment, but also in high and medium frequency surface quenching or quenching and low and medium temperature tempering.

3.35CrMo steel has high yield strength and tensile strength, and its hardness and toughness are also good. After proper heat treatment, the mechanical properties of 35CrMo steel can be further improved. In the heat treatment process, the commonly used methods include normalizing, tempering and quenching. Normalizing can improve the toughness and impact toughness of 35CrMo steel, tempering can reduce its hardness, quenching can improve its hardness and strength. Through different heat treatment processes, 35CrMo steel can achieve different performance requirements and meet the needs of different engineering fields.

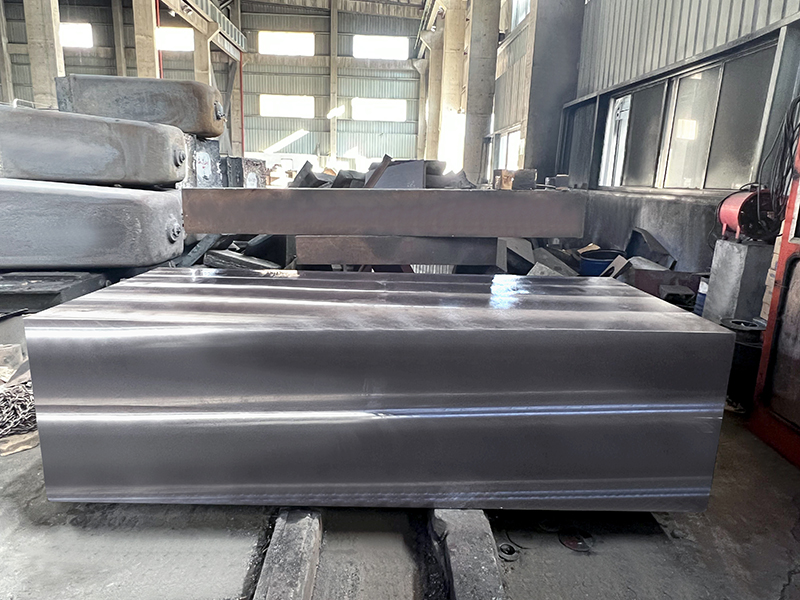

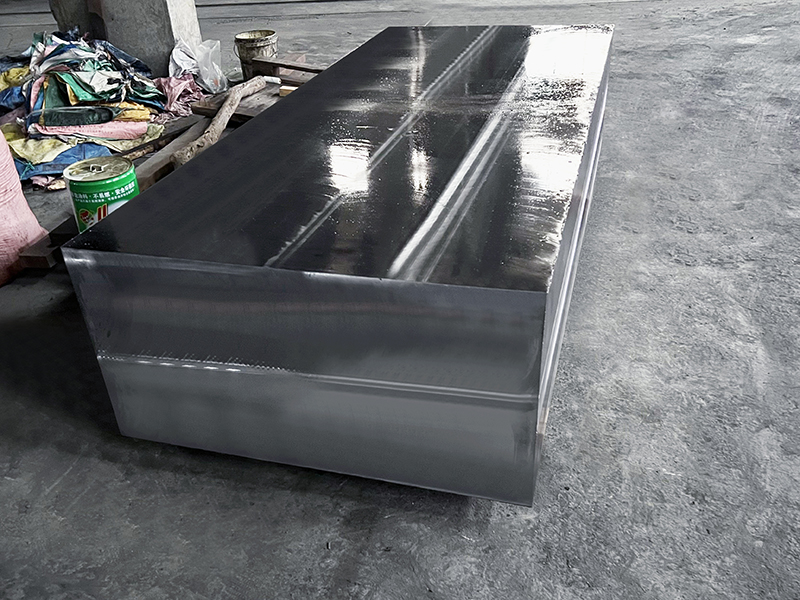

description2

Scope of application of 35CrMo alloy structural steel

1.35CrMo steel is widely used in the manufacture of construction machinery parts, such as bearings, gears, shafts, etc. Its excellent mechanical properties and heat treatment performance make it able to withstand high strength and high temperature environment working conditions, to ensure the stable operation of the equipment;

2.35CrMo steel is also commonly used in the manufacture of automotive parts, such as drive shafts, transmission gears, etc., as well as drill bits and casing in oil drilling and production equipment. In these fields, 35CrMo steel can meet the requirements for material strength, wear resistance and corrosion resistance, ensuring the safe and reliable operation of equipment;

In short, as an excellent alloy structural steel, 35CrMo steel has excellent mechanical properties and heat treatment properties, and is widely used in the manufacturing of engineering machinery parts, auto parts, oil drilling and production equipment and other fields.

Sanyao Company can provide customers with customized forging (including size, hardness, eye bolt, rough machining, quenching and tempering, rough surface grinding, fine surface grinding,etc.) to meet customers' individual needs.

Phone

Phone Send Email

Send Email