01

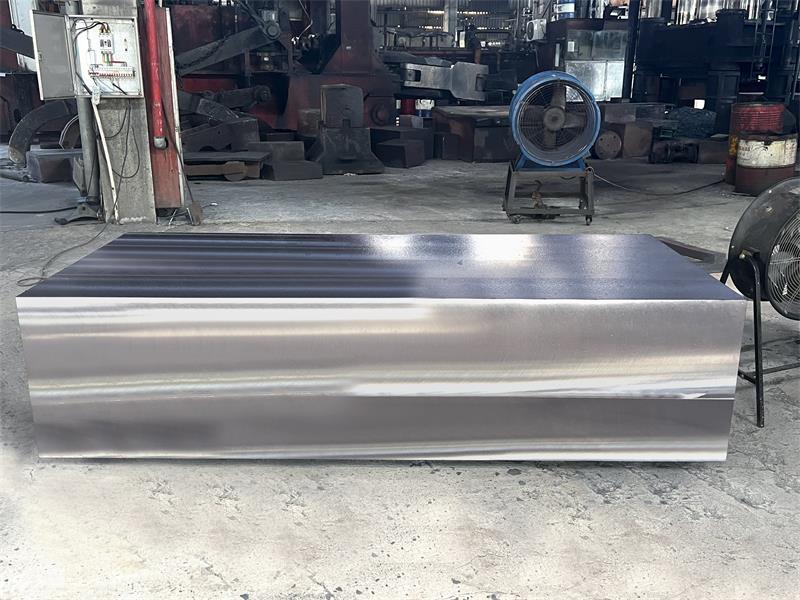

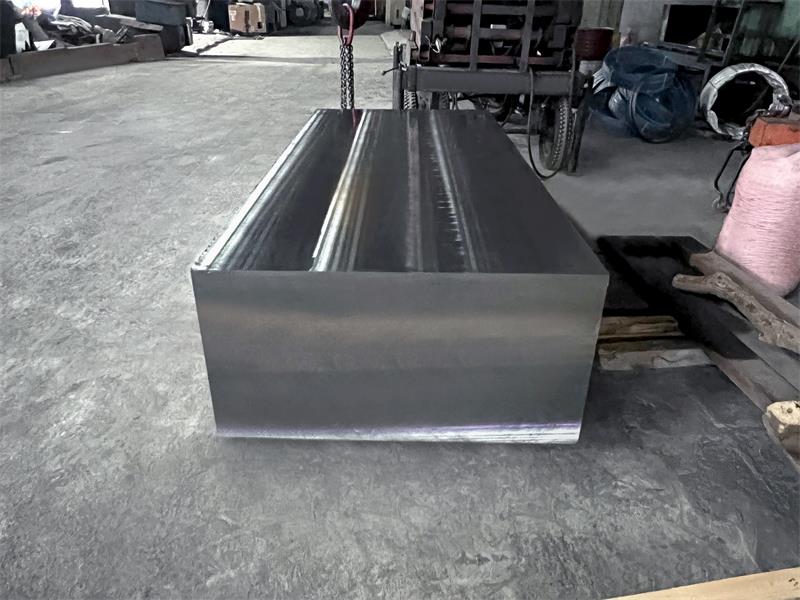

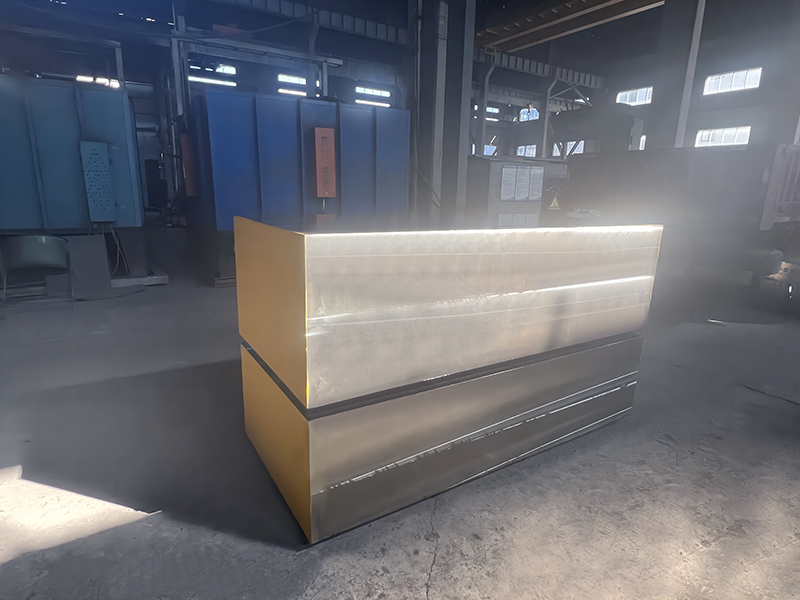

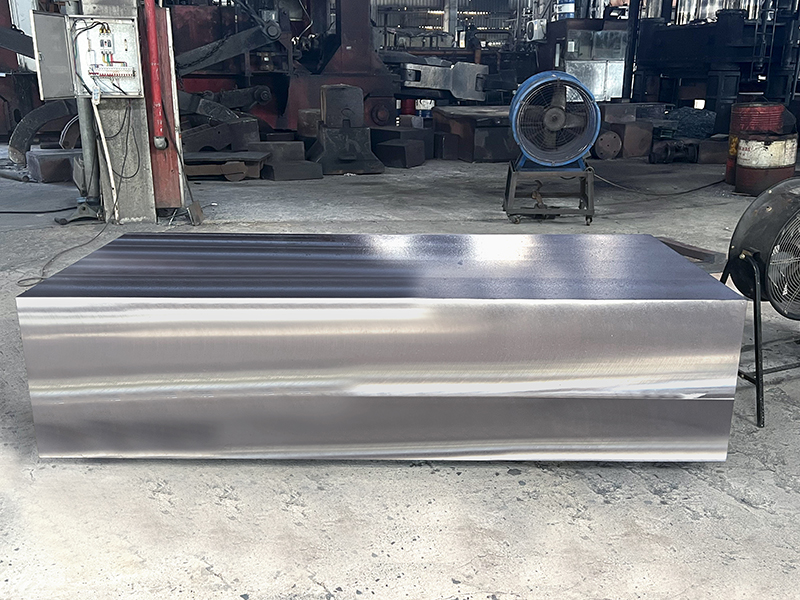

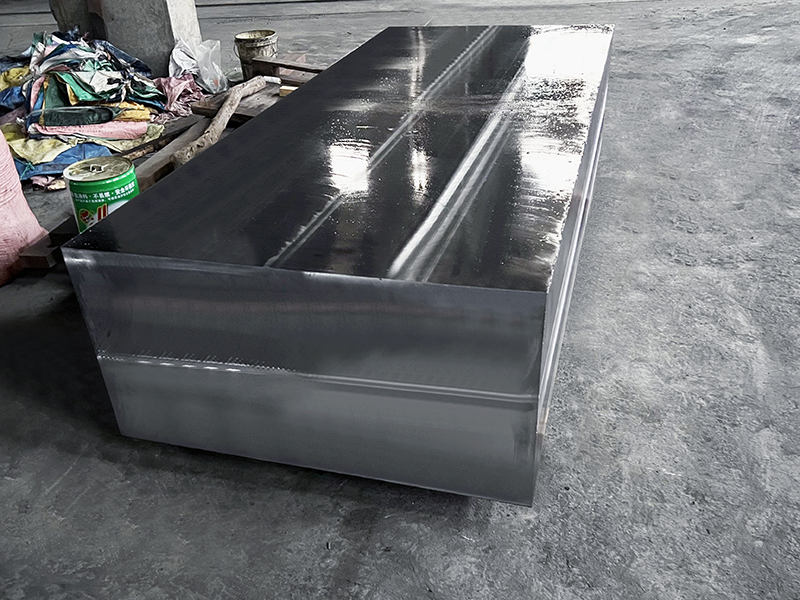

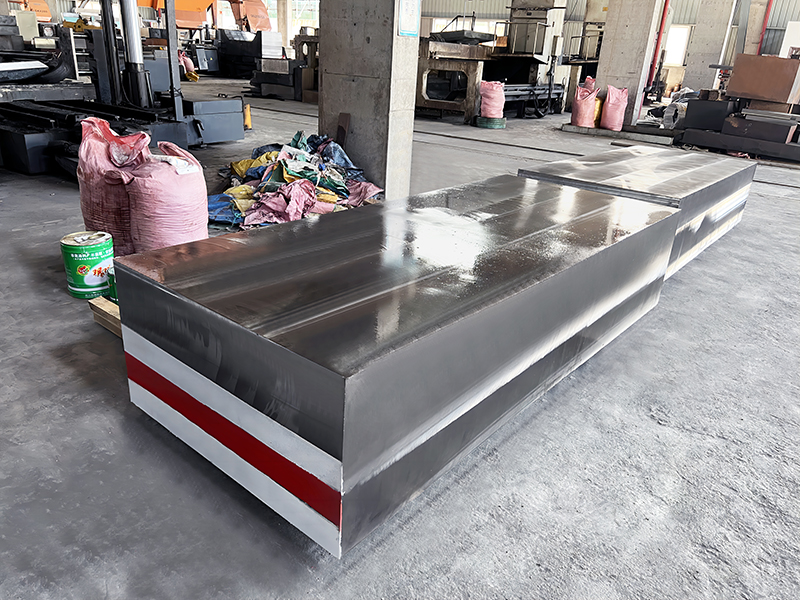

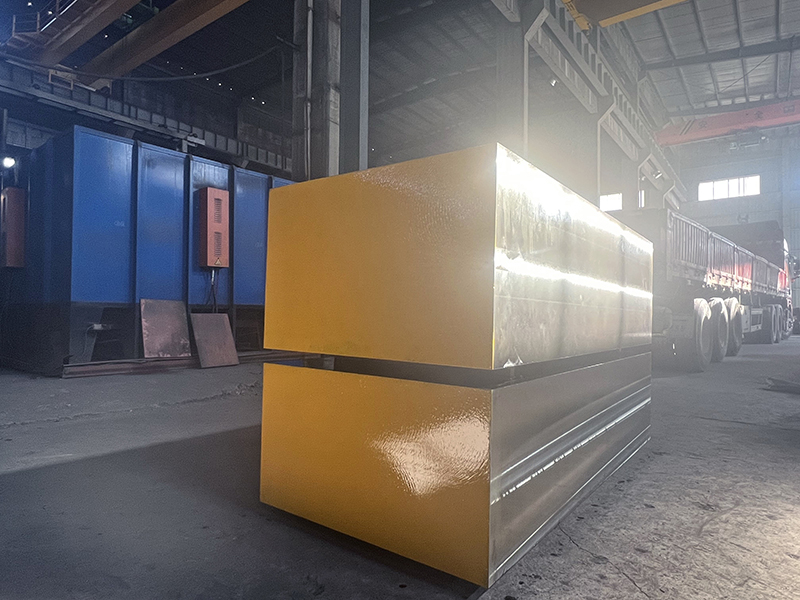

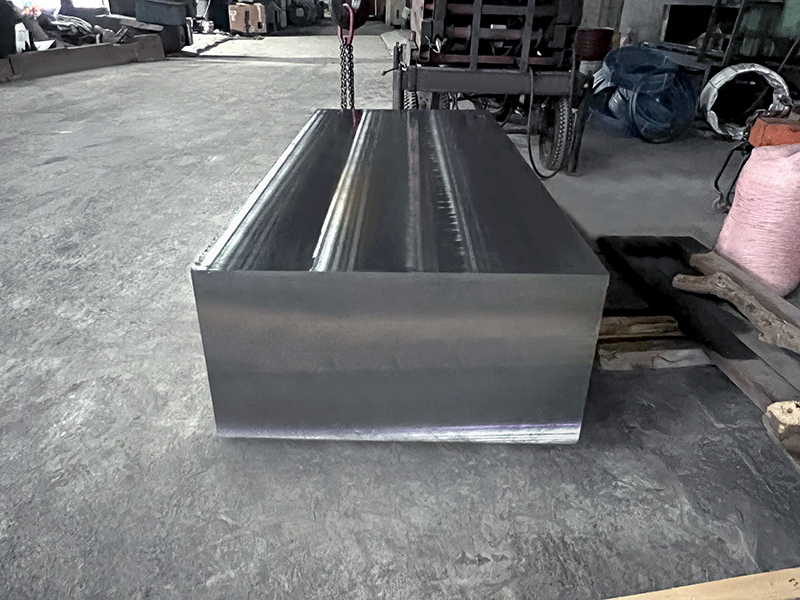

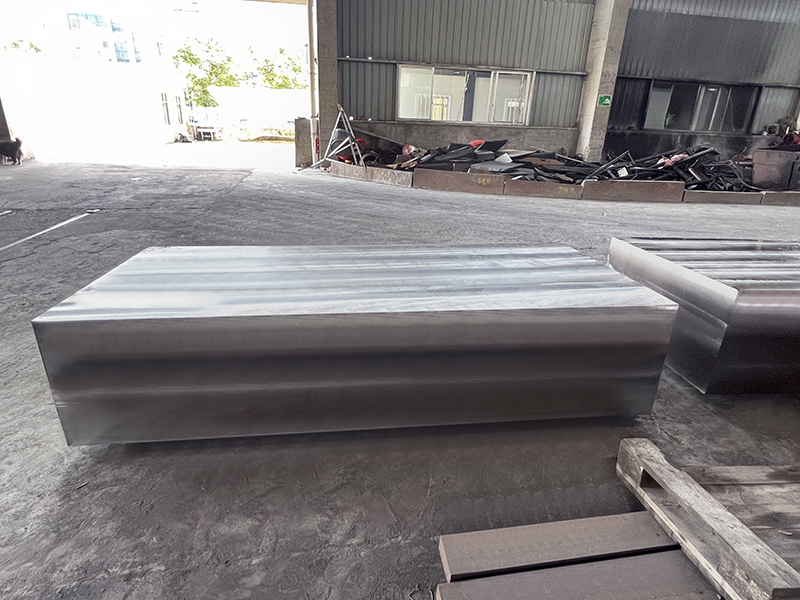

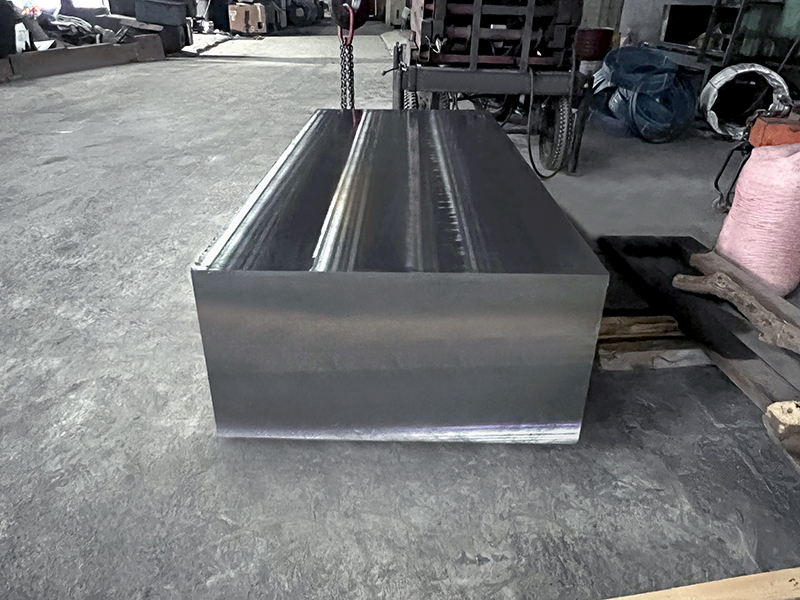

718/1.2738/3Cr2NiMo Steel

718 mold steel characteristics

1.718 mold steel has excellent mechanical properties, polishing properties, EDM processing properties and high hardenability.

2.718 mold steel is a kind of steel with high strength and high wear resistance.

3.718 mold steel has excellent hardness and anti-wear properties. Not only can it resist wear caused by high temperatures and harsh working conditions, but it can also withstand strong impacts under high pressure and high temperature environments, keeping the size and shape of the mold stable and extending the service life of the mold.

4.718 mold steel also has excellent high temperature strength and thermal stability. It is able to maintain its mechanical properties at high temperatures.

5.The machinability of 718 mold steel is also excellent. It has good thermal cutting properties and can be easily cut and processed into molds of various shapes and sizes. Whether it is a simple shape or a complex structure, 718 mold steel can meet various requirements. It is capable of manufacturing precise molds through machining processes such as milling, turning, drilling, wire cutting and grinding.

description2

718 mold steel application scope

1.Mold manufacturing and processing industry;

2.Automobile manufacturing industry;

3.Used to manufacture plastic forming molds with large batches of products, complex mold shapes and large sizes, high precision, and smooth surfaces;

4.Molds that need to work in high temperature environments, such as die-casting molds, plastic injection molds and hot pressing molds.

Sanyao Company can provide customers with customized forging (including size, hardness, eye bolt, rough machining, quenching and tempering, rough surface grinding,fine surface grinding,etc.) to meet customers' individual needs.

Phone

Phone Send Email

Send Email