Detailed explanation of the differences between forging and casting

Forging and casting are two common metalworking processes that differ in many ways. First, let's understand the basic concepts of these two processes.

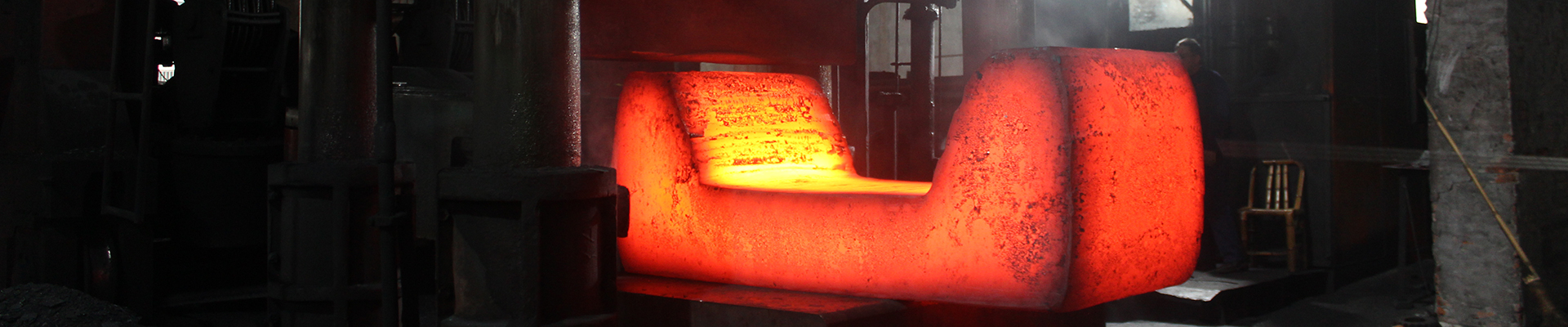

Forging: It is a processing method that uses forging machinery to exert pressure on metal blanks to cause plastic deformation to obtain forgings with certain mechanical properties, shapes and sizes. It is one of the two major components of forging (forging and stamping). It usually requires a heat source to soften the metal so it can be shaped.

Through the forging process, defects such as loose as-cast metal produced during the smelting process can be effectively eliminated. These defects may affect the strength and toughness of the metal. Through forging, the microstructure inside the metal is optimized and becomes more uniform and compact, thereby improving the mechanical properties of the metal. In addition, because the metal streamlines are completely preserved during the forging process, the mechanical properties of forgings are generally better than castings of the same material. These advantages make forging a very important process method in metal processing, which is widely used in various fields, such as aviation, aerospace, automobiles, ships, etc.

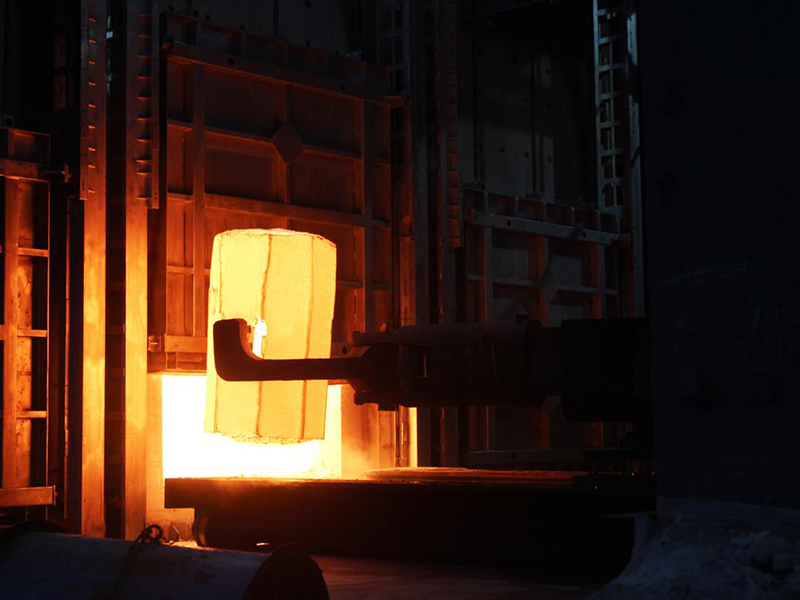

Casting: It is a method of obtaining parts or blanks by pouring molten metal into a casting cavity that matches the shape of the part, and then cooling and solidifying it. Since the casting blank is almost in shape, it eliminates the need for mechanical processing or a small amount of processing, which reduces costs and production time to a certain extent. Casting is one of the basic processes in the modern device manufacturing industry.

Casting can produce parts in a variety of shapes and sizes, and the performance of the part can be optimized by changing the metal composition, melting and processing processes.

When comparing forging and casting, there are a few key points to consider:

1. Material selection: Forging is suitable for various metal materials, including steel, copper, aluminum, etc. Casting is mainly suitable for metals with lower melting points, such as aluminum, zinc, copper, etc.

2. Strength and performance: Forged parts generally have higher strength and better mechanical properties because they are manufactured by shaping and work hardening. Cast parts may have less work hardening and lower strength.

3. Production efficiency: Casting is usually faster than forging because multiple parts can be produced at one time during the casting process, while forging requires processing one by one.

4. Cost: Casting is generally more economical than forging because casting molds can be reused and the casting process is generally more efficient.

5. Customizability: Casting is more customizable and can produce parts of various shapes and sizes, while forging is more suitable for parts of standard shapes and sizes.

To summarize, forging and casting differ in many ways. Which process is selected depends on specific application needs, material selection, cost considerations, and the strength and performance requirements of the part.

Phone

Phone Send Email

Send Email