Alloy steel

Alloy steel - On the basis of ordinary carbon steel, in order to improve the performance of steel, one or more alloying elements are purposefully added to steel during smelting. According to the different added elements, and take the appropriate processing technology, can make the steel obtain higher mechanical properties, hardenability, tempering stability, strength, toughness, wear resistance, and some also have corrosion resistance, low temperature resistance, high temperature resistance, non-magnetic and other special properties. It is widely used in the manufacture of auto parts, engineering machinery, aerospace devices and tools.

The main alloying elements of alloy steel are silicon, manganese, chromium, nickel, molybdenum, tungsten, vanadium, titanium, niobium, zirconium, cobalt, aluminum, copper, boron, rare earth and so on. Optimization and precise control of the alloy formulation are key, as they play different roles in improving the properties of the steel. For example, chromium can increase the hardness and corrosion resistance of steel, nickel can improve the toughness and strength of steel, molybdenum can improve the thermal strength and wear resistance of steel, titanium can improve the elastic modulus of steel and reduce density.

The main functions of alloying elements in steel: 1. Strengthen ferrite; 2. Form alloy carbide; 3. Refine grain; 4. Improve the hardenability of steel; 5. Improve the tempering stability of steel.

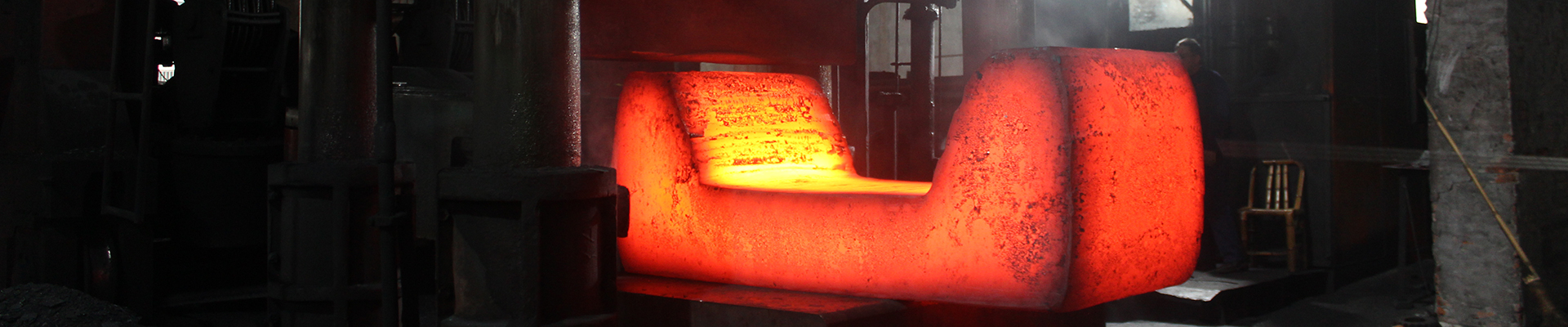

The production process of alloy steel includes steelmaking, heat treatment and surface treatment. In the steelmaking process, it is necessary to precisely control the ratio of alloy components, melting temperature and stirring intensity, etc., to ensure that the alloying elements can be fully dissolved and evenly distributed in the steel, avoiding the phenomenon of segregation and uneven organization, so as to obtain the ideal performance. Heat treatment is an important means to improve the physical properties of alloy steel, including quenching, tempering, normalizing and other processes, it is necessary to precisely control the heating temperature, holding time and cooling speed and other process parameters to adjust the structure and hardness of alloy steel, to ensure that alloy steel can obtain the ideal structure and performance, improve its mechanical properties. Surface treatment is mainly to further improve the corrosion resistance and wear resistance of alloy steel, which requires the selection of appropriate surface treatment agents and process parameters (such as coating, sandblasting and other processes) to ensure that the alloy steel surface can form a uniform and dense protective layer, improve its corrosion resistance and surface hardness.

There are many kinds of alloy steel, usually divided into low alloy steel (content <5%), medium alloy steel (content 5% ~ 10%), high alloy steel (content >10%); According to the main quality grade is divided into: high quality alloy steel, special quality alloy steel; Classification by use: divided into alloy structural steel, alloy tool steel and special performance steel. The alloy structural steel can be divided into low alloy high strength steel, free cutting steel, carburized steel, tempered steel, spring steel, rolling bearing steel and so on. Alloy tool steel can be divided into cutting tool steel (including low alloy cutting tool steel, high-speed steel), die steel (including cold die steel, hot die steel) and measuring tool steel. Special properties of steel are stainless steel, heat-resistant steel, wear-resistant steel and so on.

In summary, alloy steel as a multi-functional material, its production process is relatively complex, but through the precise alloy formulation design, steel process control and heat treatment process optimization, can obtain the ideal performance and quality. In the future, with the increasing demand for high-performance materials in engineering manufacturing, alloy steel will continue to play an important role and become one of the mainstream materials in related fields.

Phone

Phone Send Email

Send Email